How to fix loose and rattly bridge screws

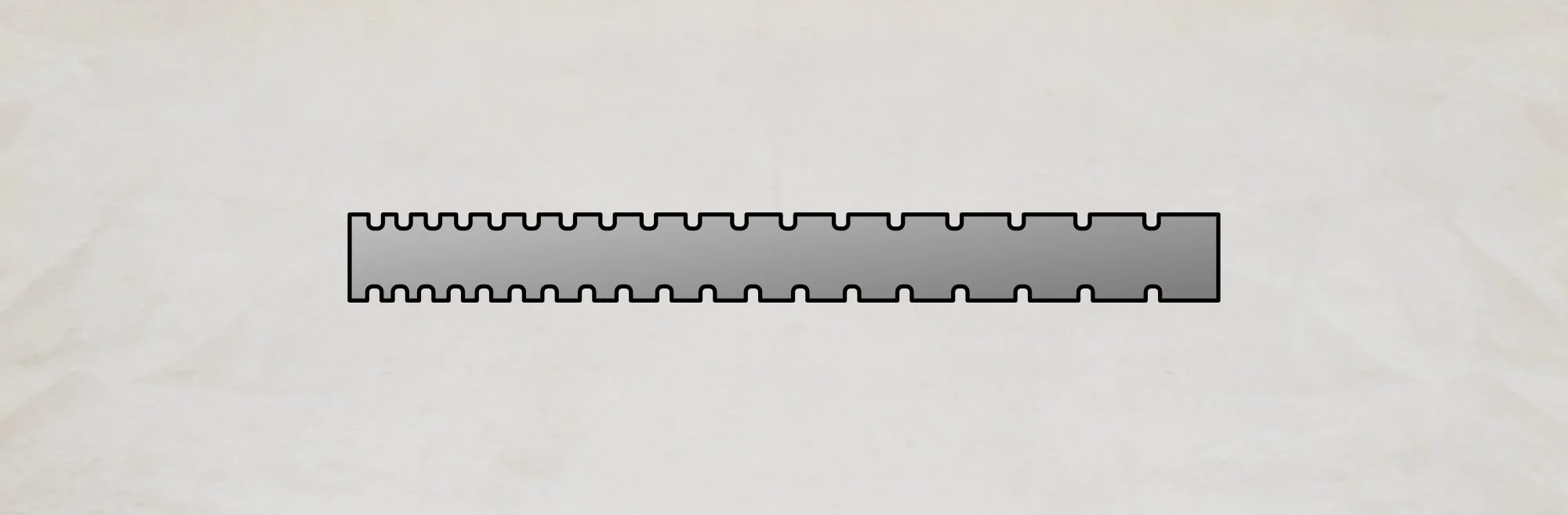

Let’s talk self-loosening screws. The height-adjustment screws on some bridge saddles can work themselves loose over time. You might spot one screw from a pair has mysteriously raised up. It’s likely to rattle and, if not tightened up again, it’s not unusual for it to fall out completely. I’ve seen more than one bridge with missing screws because of this crazy phenomenon.

Why do bridge screws loosen and raise

You’ve probably figured out that it’s the vibrations of string and body that are shaking these screws loose.

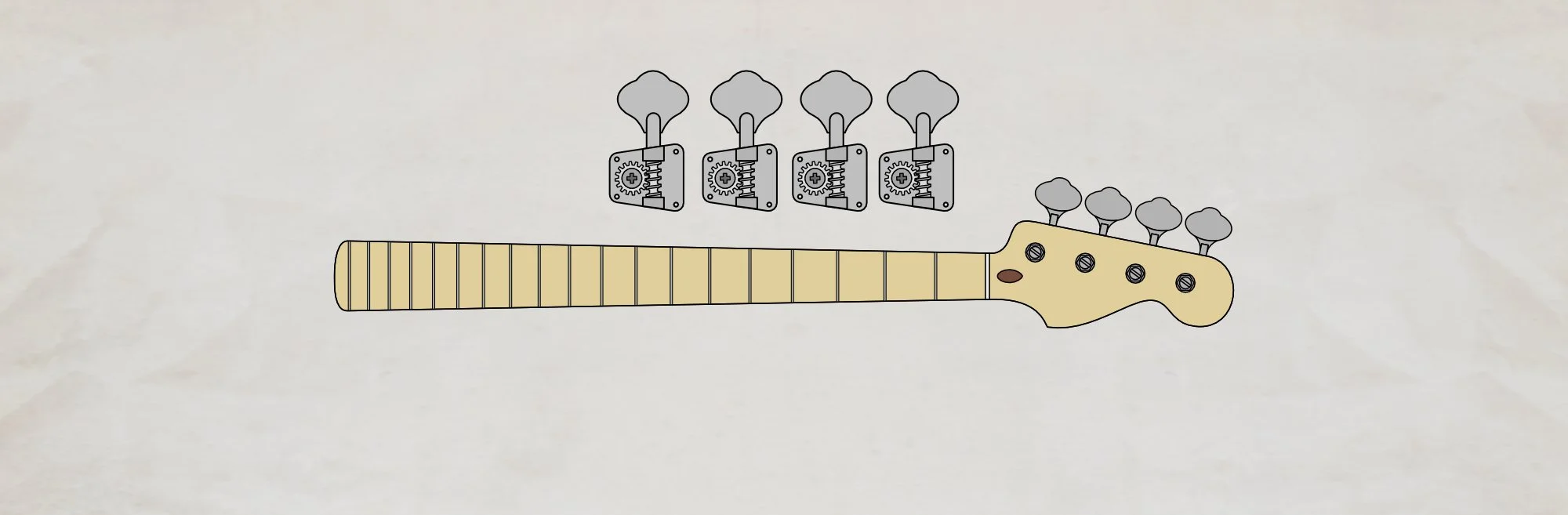

You’ll find it frequently on Jazzmaster and Jaguar bridges; because the strings break over the bridge at a shallow angle, there’s not a lot of downward pressure to press against the saddles and ‘lock’ the screws in place.

This is also a very common problem on the budget bridges you might find on cheaper copy guitars (like the image below). You can see the gap under the screw.

What’s to be done?

How to prevent loosening saddle screws

Lock ‘em in place. That’s the way.

Now, I’ve seen people use PTFE or plumbers tape to add a little thickness to the screw and, while that’ll probably work, it’s always seemed massively fiddly to me.

There’s a much easier way.

Use a thread-locking fluid

Most bigger DIY stores will have a thread-locking fluid. Loctite make a number of different kinds, for instance. This can be dabbed on the screw threads before it’s screwed into place and, when it cures, it’ll ‘glue’ the screw in place.

The clever bit is that it’s designed to resist vibration but will ‘let go’ if enough torque is applied.

If you’re going down the thread-lock route, make sure you don’t accidentally apply the high-strength stuff. The low-strength stuff is fine. Low strength is generally a purple colour and will release without too much torque. Medium strength (that’s blue) will probably be ok but I’d still prefer low. Definitely don’t apply a red thread-locking fluid or you’ll never adjust your bridge again.

But there’s an even easier way

Lacquer or nail-varnish

Don’t want to go buy a thread-locking fluid? I got you covered.

Just use a tiny drop of clear nail-varnish. I use a little nitrocellulose lacquer when I’m doing this job and that’s pretty much the same.

You might have some nail-varnish around the place or be able to scrounge some up easily. You’re only going to use a couple of drops (so, if it’s not yours, it shouldn’t cause any arguments).

How to apply

Caution: Mask around the bridge with some tape or paper to prevent any drips or splatter getting on the paintwork. This is especially important if your instrument has a nitrocellulose finish. Newer finishes, you could probably wipe up a drip but nitro could begin to dissolve under a drip of lacquer or nail-varnish. Be careful.

I’d advise making sure that your saddles are set up just as you like them. Get your action right.

Put a little blob of lacquer/nail-varnish/thread-lock on something disposable and non-porous. I tend to use an old plastic string wrapper.

Note the position of the first saddle screw and back it out of the saddle a little.

Use a toothpick to transfer a little of your locking fluid of choice onto the threads of the screw. Obviously, it should be applied to threads that are going to be inside the saddle when you’re done.

Screw it back into its original position and wipe off any drips.

Repeat for the other eleven screws.

All going well, tomorrow, you should have some screws that are a lot more rattle-resistant.

An Untested Alternative

When I sent this information to the Haze mailing list (you should sign up — all the cool kids are doing it), I got an interesting response form Alex (thanks, Alex).

Alex said the some mechanics will use linseed oil as a locking fluid. A very tiny drop of linseed oil will (after a while) cure into something gummy and then something hard. At the time of writing, I haven’t tested this but, in theory, it seems a reasonable alternative if you happen to have some about the place. If I have a reservation it’s that I suspect the curing time might be longer than the lacquer or thread-lock.

If you’re going to try this, I’d advise the same precautions about masking and only use a tiny amount. Make sure to wipe off anything that drips or seeps as you don’t want it getting gummy in places you don’t want getting gummy.

A further note on Jags and Jazzmasters

Worth mentioning that the shallow string break-angle can cause a few problems with these guitars. Options to address some of these issues include, bridge replacements, angle ‘adjusters’ like the Buzz Stop, and neck shims (to change the neck angle).

If you’re considering some of these solutions, personally, I’d shim first and go from there.

This article written by Gerry Hayes and first published at hazeguitars.com