Unusual Acoustic Guitar Bridge Repair

Ok, so you’ve got to admit that's a little unusual.

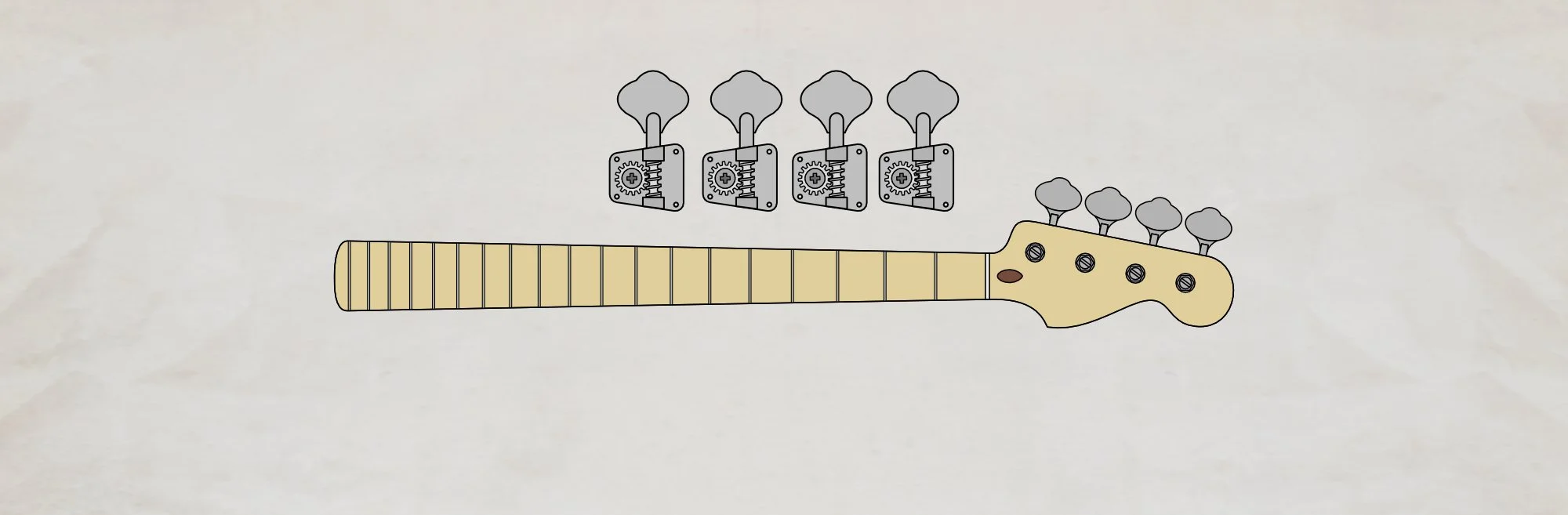

What we’ve got is a tailpiece installed on this Takamine. It’s anchoring the strings which pass through the (pinless) bridge and up over the saddles.

Whatever else, it’s an inventive solution to some sort of problem.

Thing is, it’s not the best solution. The tailpiece is resting against the top of the guitar with isn’t the best for getting a good tone. Also, the guitar’s designed to have strings couple to the bridge for good transfer to the top.

You can see the problem this was trying to solve. The original bridge had cracked and was starting to disintegrate where the strings anchored.

Along the way, someone had installed a third bolt right in the middle to try keep it together. You can see the filler sunken in between the D and G strings at the rear or the bridge. These bridges already have a couple of bolts installed to help keep them from ripping free and flying across the room. Once this crack happened, though, no amount of bolts was going to help.

So what’s to be done?

Bridge Repair

The damage to the bridge is too far gone for a sound repair. There are two choices here:

Replace the bridge completely: Not the most cost effective as it’ll likely mean custom-cutting a replacement bridge. Since these Tak bridges are designed to accommodate their palathetic pickup, including a split-saddle, that means a very, very fiddly and time-consuming job.

Get a bit cheeky and just replace ‘half’ the bridge.

We’re going with number 2.

Removing ‘half’ a bridge

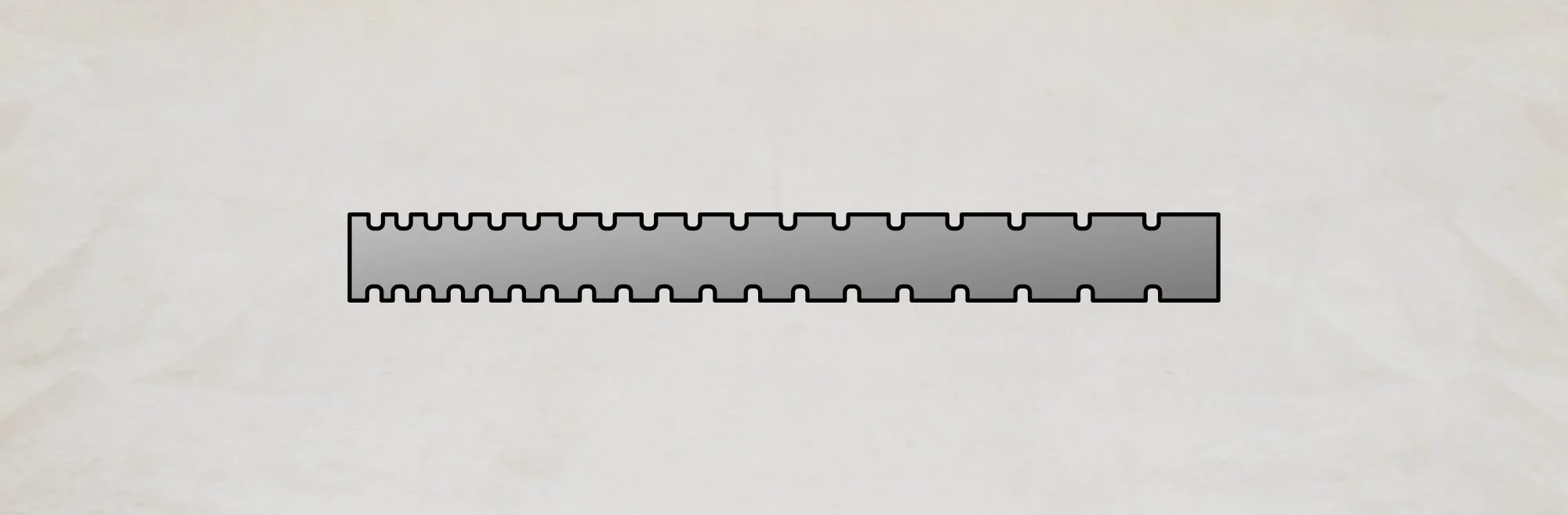

Since we’re going to avoid the saddle slots with their related awkwardness, I’m going to remove the back half of the bridge. Essentially, I’m just taking off the damaged part.

Removing it is relatively straightforward. I chose to rout off the rear section in a straight line, bringing it close to the top but not quite touching. I finished up with chisels.

I didn’t rout all the way to the bottom of the bridge because a guitar top has a radius — it’s domed. My router was resting on a makeshift jig (to get that straight line) and wouldn’t have matched this dome.

Also, I couldn’t apply heat to make the glue let go as I wanted to maintain good adhesion on the front section. Routers and chisels is the way to go.

Making a new acoustic bridge… Piece

The basic shape of the new bridge is easy enough to rough out of a rosewood blank. Then some ‘finessing’ to get it to shape. It’s important to get the ‘footprint’ correct but I’ve left it higher than the existing bridge.

Drilling the mounting holes and the string holes needs a bit of care as you don’t want these to be misaligned of out of place.

As there was already a third hole in the guitar top (one more than would usually have been there) I chose to go with a third bolt on this repair. I wouldn’t have added it unless there was already a hole but I figured it’d give some more security since it was already there.

Once everything has been shaped and cut, we still need to pay attention to the bottom of the repair piece. Remember that ‘dome’ on the guitar top? the bottom of this piece should match that so it mates well. Glueing a flat piece of wood on a domed surface can be problematic. Some fiddly sanding of the bottom will give me a good match.

Glueing on half an acoustic bridge

You can see from the photo below that I’ve installed two of the three bolts. These aren’t actually tightened down as part of the glueing — they’re just there to help align things and keep the piece from slipping around.

Incidentally, that large wooden cam clamp bears some explanation. You would, ordinarily, never clamp onto the middle of a soundboard like this as you could damage it. I have a couple of jacks installed inside the guitar to prevent the clamp ‘crushing’ the top or back. Even so, I was pretty careful with the pressure applied — I just wanted to ensure the rear of the piece was properly mated.

Final bridge fit

Once the glue is dry, I can take the top down to the correct height with a sharp chisel. It’s much easier to do this in place than to try get a match off the guitar. Some sanding and clean up and I can install a couple of inlay pieces to cover the bolts.

String it up. Hope it holds. ;-)

Phew.

It probably won’t be as much of a conversation starter as a honking great tailpiece but I reckon the guitar looks and sounds a lot better now. This Tak lives to fight another day.

This article written by Gerry Hayes and first published at hazeguitars.com