Cheap alternative to guitar nut files?

After the last few articles about fitting a new nut (and the hassle that can go with it), it makes sense to discuss something on nut files.

Properly gauged nut files are the bugbear of DIY guitar-setter-uppers. They’re not cheap and there’s no really good substitute for them.

Or is there?

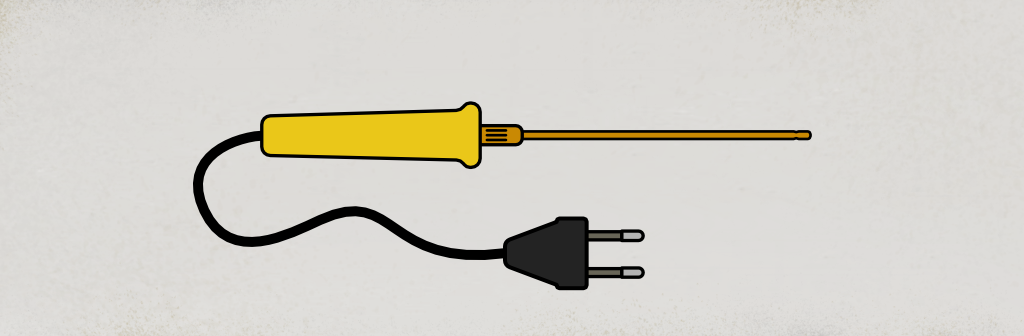

For the last while, I’ve been seeing more and more about a super-cheap alternative. Someone in the guitar world discovered that welding torches have differently sized nozzles and that those nozzles have to be cleaned with differently sized cleaning probes. These probes are gauged to fit the nozzles and have a ridged, abrasive portion.

Maybe that can be repurposed to cut a nut slot, they thought. Makeshift nut files. Brilliant!

Is it brilliant?

I tried some out.

First some more context on these. Can you feel the anticipation building? 😉

Welding Torch Nozzle Cleaners as Nut Files?

These things are available all over the internet for a couple of bucks. Search eBay for welding nozzle tip cleaners (affiliate link) and you’ll find them for next to nothing. Interestingly, since this tip-cleaner-nut-file crossover thing has become more talked-about, if you now search eBay for nut files, you’ll find these exact same nozzle cleaners costing much more. Capitalism in action.

Anyway, these are just a small folded metal ‘case’ containing a number of gauged ‘probes’ (for want of a better word). They seem pretty standard but the ones I bought have 13 cleaners and a small metal file).

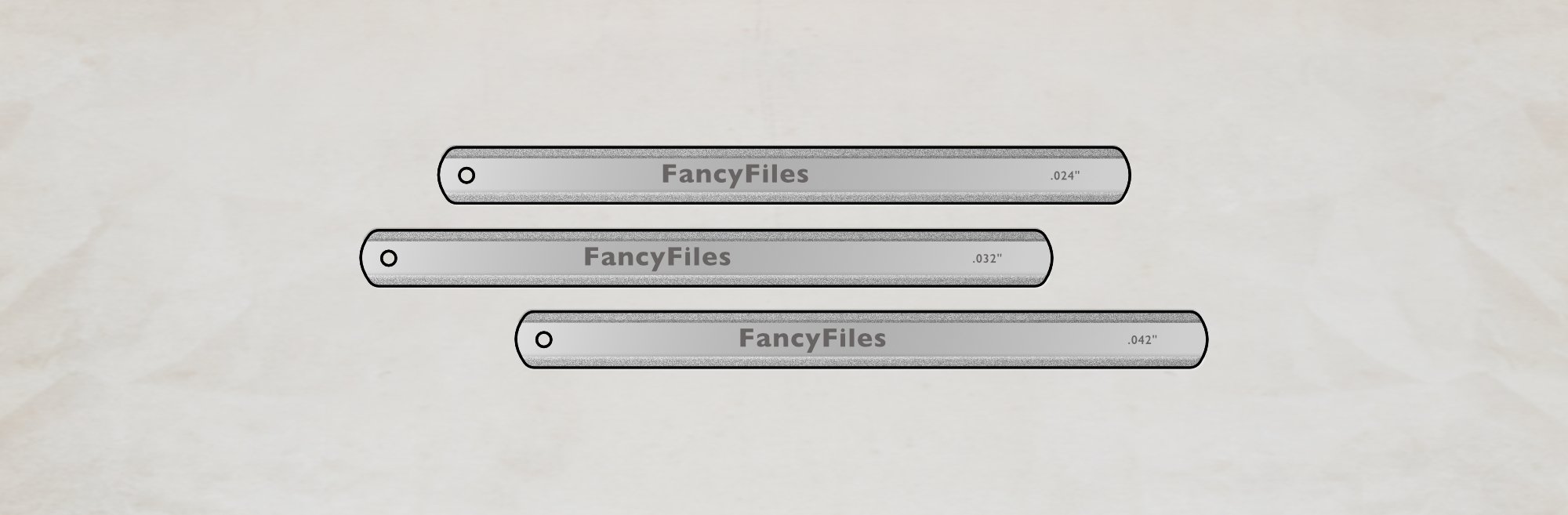

There’s a stamped table on the case detailing the nozzle number (means nothing unless you’re a welder) and a numbered drill size (a system for identifying very small drill bits). This latter is probably not terribly useful for most of us either.

So, I went and measured each one. Interesting to note that some differ from the listed drill size. The differences aren’t much in most cases but, if you decide to use these, it’s worth bearing in mind.

The measured size column below shows the diameter I found each cleaner to be. This is listed in decimal inches because that’s what most string sizes are listed in.

| Tip Cleaner Size | Drill-Bit Size | Measured Size |

|---|---|---|

| 6 | 77-76 | 0.016” |

| 7 | 75-74 | 0.020” |

| 8 | 73-71 | 0.024” |

| 10 | 70-68 | 0.028” |

| 12 | 67-65 | 0.031” |

| 14 | 64-62 | 0.035” |

| 15 | 61-60 | 0.039” |

| 16 | 59-58 | 0.044” |

| 17 | 57 | 0.048” |

| 18 | 56 | 0.052” |

| 22 | 55-54 | 0.056” |

| 24 | 53-52 | 0.059” |

| 26 | 51-49 | 0.065” |

So, right off the bat, the glaring omission is any size smaller than 0.016” (i.e. the top two strings on many guitars). Ok. Let’s shelve that for now and check out how they work and how to use them.

Review: Using Welding Nozzle Cleaners to Cut Nut Slots

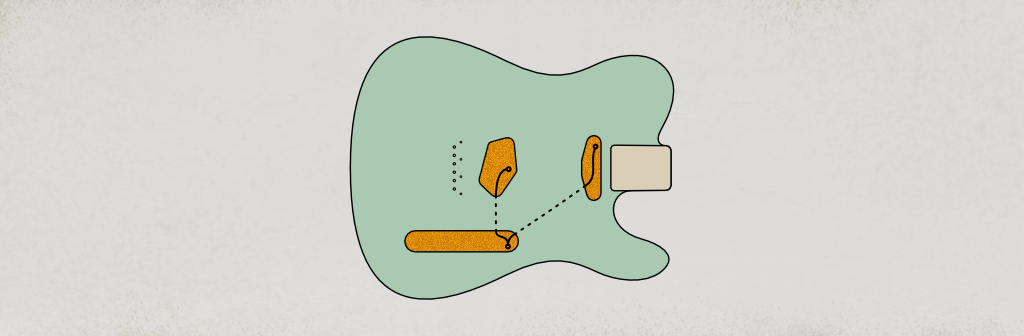

I popped a couple of scrap nuts into my vice and set to work. Using a pencil, I marked a position about 0.015” below the bottom of the slots (very roughly) and aimed to lower the slots to that position.

Did it work?

Well, yeeeeeeaaaah… It did. But, some big caveats here.

First off, it was really hard to do. It took a very long time compared to doing the job with, you know… and actual tool. But that’s ok. The point is to find a cheap alternative, not a better alternative.

The biggest problem I found was how to keep the cleaner probe straight. And it’s really important to keep it straight.

Let me explain: Some pressure on the probe (like when you’re trying to cut with it) bends it really easily. Shown below is one of the larger probes and it really wants to deform under finger pressure. This is made progressively more troublesome as the cleaners get lighter.

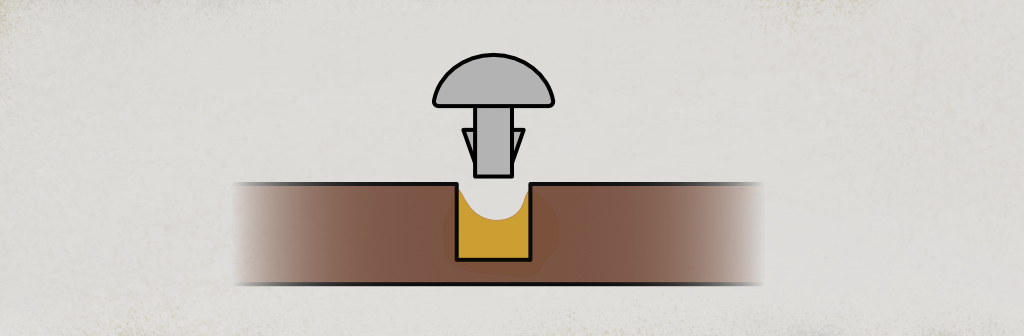

If you don’t keep that cutting implement straight, you really risk cutting some weird shape into the length of the nut slot. It’s really likely to cut a ‘ramp’ on the front of the nut slot and that’s a recipe for setup and intonation troubles (as illustrated in the repurposed image from Solving Intonation Problems below).

I could just about keep the heavier probes straight but this slowed cutting progress. For the lighter probes, the only way I could even get close to straight was to grip the cleaner with one hand at either end and try to ‘tension’ it as I sawed back and forth. Not easy.

And clogging was a problem. The abrasive file-like notches in the cleaning probes loaded up really easily. Before I knew it, the grooves were filled with filed material from the nut and cutting ground to a halt. Running a finger along the probe felt almost smooth, the grooves were so clogged. So, I ended up using a wire file-cleaning brush often to brush this material away and expose some cutting surface again.

All of that said, I did eventually get where I wanted to be. It just wasn’t fun and I have my concerns about the accuracy of the final slots, even being as careful as I can.

Do I Recommend Welding Torch Cleaners as Nut Files?

Hmmm. This is a tough one. I know that not everybody can afford a set of nut files. I know that nuts are the big problem in any DIY setup. And, as we’ve discussed recently, getting string slots at the right height without them is a nightmare.

So, I really want to be able to recommend these things. I want to be able to tell you that for a couple of bucks you can have something serviceable, that’ll do the job.

But can I?

Sort of. But also, no.

On the ‘pro’ side, these cost almost nothing and can work if you’re really careful and really patient. And if you have fingers as strong as your will power.

On the ‘con’ side, they’re really difficult to achieve a good result with. As the probes get lighter, they get harder and harder to use well. And, the big problem is that there’s nothing small enough to deal with the top two strings on many guitars.

I’d hate to have to completely fit a nut with these things. I can see some use for these in the very final fitting stages of a pre-cut nut — where you’ve gotten most of the way there by sanding the bottom and you just need to finesse those final few thousandths of an inch. Or some adjustments to make the string slot radius on your pre-cut nut more closely match your fretboard. In limited use-cases, if you’re careful, these things could be an alternative to regular nut files.

And that’s the best I can do. A wishy-washy, maybe-sometimes-but-with-reservations recommendation.

Like I said, you’ll get ‘em on eBay (affiliate link) for a couple of bucks so it’s easy to have a go if you’re inclined. They’re on Amazon too but tend to be more expensive.

Long story, short: These might get you where you want to go but the journey is hard and the destination comes with a heap of caveats and disclaimers. If you can swing it at all, get yourself a good set of gauged nut files. Maybe ask your guitar pals and club together to get a communal set (I’ll have them Mondays, Wednesdays, Fridays, and every second Sunday — that sort of thing).

P.S. As a slight aside, I’ve noticed that eBay has some more ‘proper’ looking double-sided nut files direct from China for very little money. Worryingly little, if I’m honest. I’ve ordered up a set and will check them out and report back to you. When they get here. Don’t hold your breath, though. Cheap shipping from China tends to be on the slow side.

This article written by Gerry Hayes and first published at hazeguitars.com