Shimming a Low Guitar Nut with Hardwood

Since I wrote about Takamine guitars often having shims under their under-saddle pickups, I sometimes get emails asking if I can supply these shims, or know of anywhere that can. The answer’s no, by the way. At some point, I’ll do so digging to see if I can find something similar to the Takamine shim (some sort of phenolic/resin fibre board thing, I think) but, so far, I haven’t had the time or masochistic drive to go looking.

However, I recently stumbled across a very odd source that can supply some hardwood shims.

Hardwood shims can be really useful and anyone doing this job will likely find more than a couple of uses. Joint reassembly after a neck reset, for instance, usually requires some shimming. Similar repairs, ditto. In the past, I’ve even used this sort of thing as a veneer over a not so pretty repair.

We often need to shim under saddles to try raise the action without having to make a new saddle. And, as the title of this post will have tipped you off, sometimes we shim nuts.

If the string slots in a nut are cut — or have worn — too low, the open string will buzz against the first fret when it’s played. That sucks.

In an ideal world, we’d remove that nut and replace it with a nice new nut. But of course, it’s not always an ideal world. Maybe the guitar’s a beater and you don’t want to fork over a heap of cash. Maybe you’ve already forked over a heap of cash for other repairs and you can’t run to the extra for a new nut. Sometimes, an alternative is needed.

Shims.

Raising up the nut will obviously give more clearance in the string slots. If you’ve been around guitars a lot, you might have come across a nut that’s got a hunk of business card stuck underneath. That’s not great. Cardboard isn’t the best material to ensure a good solid coupling of nut and neck and to prevent string vibration being prematurely killed off.

Of course, while we’re on the subject, any shim isn’t the best way to go. Ideally, you’d have no shim at all but, well… read that stuff above about an ideal world again. If you’re going to shim, at least shim with a good material. A hardwood shim, made from wood like the neck itself, is a great way to go.

Quick Sidenote: Another great substance to shim a bone nut or saddle is bone. Luthiers Mercantile have sold bone shim stock for a while. Problem is, it’s really hard to work. Bone is brittle in such thin layers. I’ve used it (and still do sometimes) but using wood shims is so much easier and just as good in most cases.

Sourcing Hardwood Shims

I have the distinct advantage of having access to a bandsaw. With a nice fresh blade, and some care, I can make some pretty thin shims. In the past, after changing blades, I would spend a while cutting scrap wood into shims of various thickness. I still do.

However, I’ve found I can get a nice heap of, well cut, consistent-thickness shims of around .6mm (0.024”). This is a nice, useful size and the consistency is better than I can achieve. So, now, I just buy from this unusual source.

What is it?

Doll’s house floorboards.

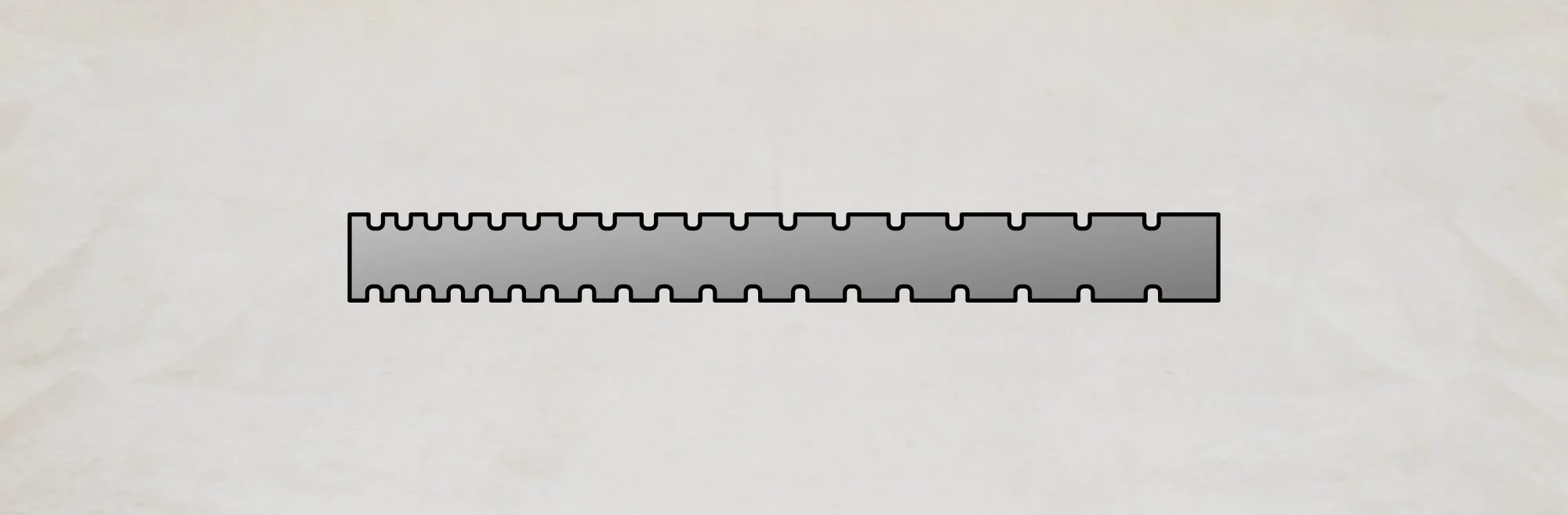

Those people who meticulously craft doll’s houses need floorboards. So, it’s possible to buy long, thin strips of hardwood that’s intended to floor a doll’s house but can easily be turned to other, more guitary jobs.

The floorboards I’ve been using come sized as ½” wide by about 12” long by 0.024” thick (about 12 x 300 x 0.6mm).

Get them on eBay (affiliate link) where they’re quite reasonably priced for a bundle of twenty eight. They’re available in a number of different wood varieties. I use mahogany for most stuff.

Now, in reality, these 'floorboards' are just short pieces of what's called 'edge-banding'. It's used in cabinetry and furniture-making to cover the edges of something like plywood or chipboard to make it look nicer. It's essentially a narrow, glue-on veneer. If you want to buy 15 metres of the stuff, you can do so but, if you just need a little for a couple of shims, dolls house floorboards work pretty well. 😉

Shimming a nut

So, how to use this stuff…

First off, there’s an adhesive coating on the ‘rear’. We don't want it. It scrapes off quite easily.

Make sure the bottom of your nut is clean and flat. If there’s any glue residue sand it off. Place some sandpaper (220 grit should be fine) on a flat surface and rub the nut on that — don’t rub the sandpaper against the nut. This helps ensure a flat bottom.

Put the shim on a flat surface. Apply a film of superglue over the bottom of the nut and press it down firmly unto the shim. I like to spray the shim with a little superglue accelerator before glueing, just to speed things up. Otherwise, be patient while keeping pressure on (please don’t glue your fingers — I’m trusting you to be careful) as superglue doesn’t always cure as quickly as you think (unless it’s on your fingers, in which case it’s really fast — be careful).

When you’re happy it’s secure, you can use an exacto knife to trim off the excess wood. A little work with the sandpaper can clean up the edges nicely.

Now, before we all start slapping each other on the back, I should mention that there’s a good chance your nut is now too high. While this is usually preferable to one that’s too low, we should (ideally) follow up with some filing of the slots for a perfect setup. Ideal world, right? You can do some additional sanding on the bottom of the shim, once it's glued to the nut, to get a better height (in the same way you would if fitting a new pre-cut nut).

Other shims

This stuff is pretty handy for joint shimming and for nuts. For saddles, it can be perfect too, but that depends on how much you want your action raised. You might have to repeat the process and add a second shim under the first. You can do a little sanding of the bottom to finesse the action back down if needed.

Other materials can be used for shims, of course. I’ll dig into that Takamine stuff for the future but, you’ll frequently see copper and brass shim stock in various thicknesses. This will work for some applications (not great for joint-shimming or nuts where glueing is concerned) but it could be pressed into service under lock-nuts and under saddles. I haven’t gone into much detail on it as it’s harder to work and most people won’t have the tools to cut it, especially in thicker versions.

For me, even though I can make shims myself, I’m quite happy to have a bundle of doll’s house floorboards to save me some time and effort.

If you think shims of this size could be useful, go get some floorboards. 😉

P.S. There are some alternatives to repair nuts with low string slots. More on that next time.

Written by Gerry Haze and published at hazeguitars.com