Drilling broken screws out of guitars

Over the last couple of weeks, we’ve looked at a few methods to extract worn or damaged screws. The methods discussed mostly assumed that we were dealing with a worn screw — one in which a screwdriver was no longer able to get a grip to turn it.

But what about when things are even worse and the screw head has broken off?

Well, sometimes, you get lucky and there’s some screw shaft still protruding and it’s possible to grip it with your screw removal pliers.

More likely, you’re unlucky and you have to resort to drilling again.

Drilling out a broken screw

OK, first off, I’m going to describe how to do this using a set of tools available from Stew Mac: The ‘Guitar Screw Rescue Kit’. It’s absolutely possible to drill out a screw without this but this is the cleanest and easiest way of getting this job done for smaller screws. I debated about getting this stuff but it’s turned a job that was a pain in the ass into one that I really don’t mind. I’ll talk about alternatives in a bit but, for now, here’s a little about the Stew Mac kit.

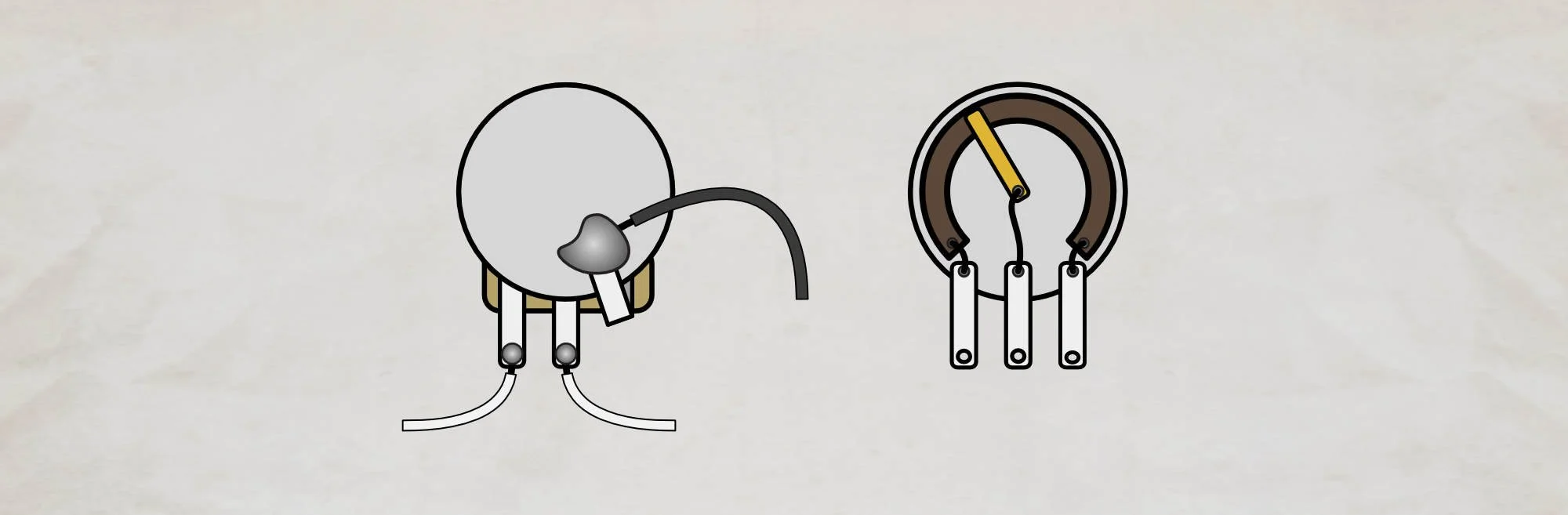

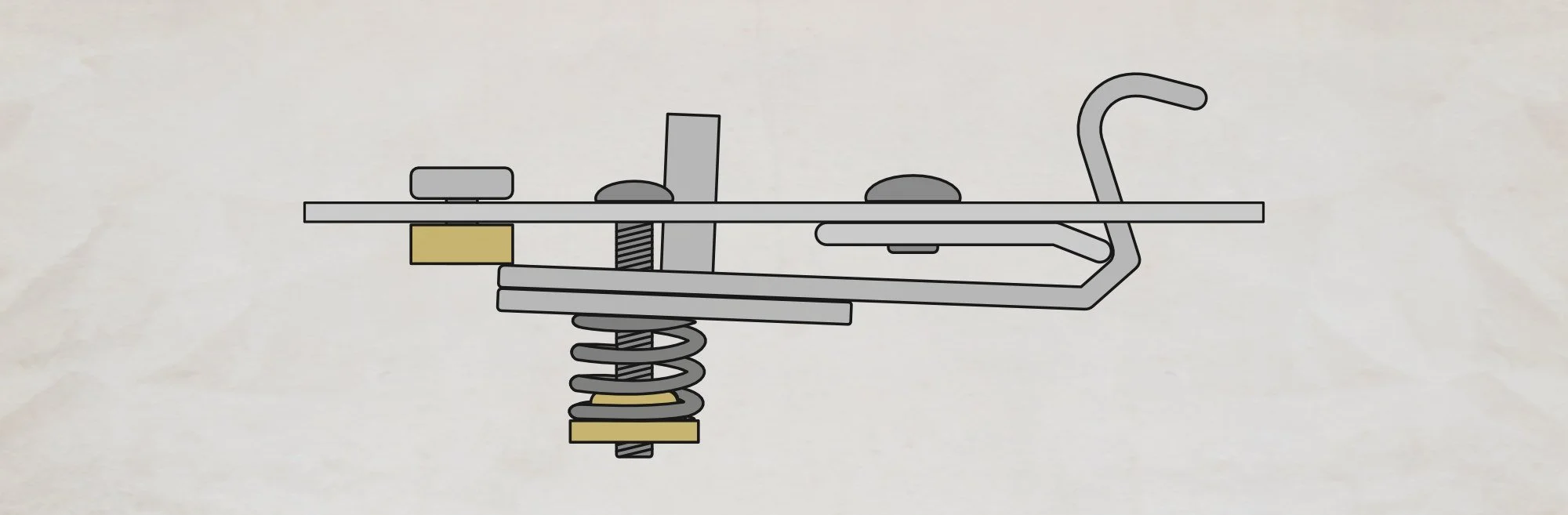

The best part of the kit is the ‘extractor’. This is a steel tube with teeth on the end — it’s a cutter. The idea is that you centre it over the broken screw and it drills through the surrounding wood to the depth of the screw (or close enough to let you grip the screw with a needle-nosed pliers.

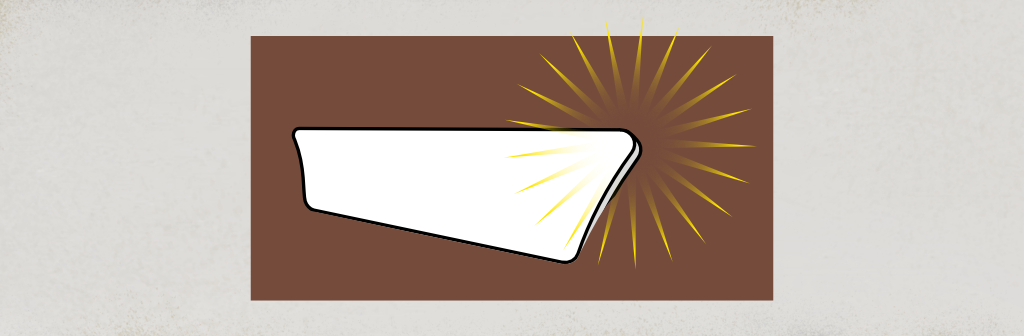

This particular cutter cuts in reverse (hence my reminder on the plexiglass guide). Run it relatively slowly and keep taking it out to blow away waste. Doing this lets you check how you’re getting on and helps prevent the screw and wood getting stuck inside the extractor tube like some jammed-in core sample.

You’ll be left with a clean hole where there used to be a screw. Just use the plug cutter to make a perfectly-sized plug from a matching timber. Glue in the plug and you’re all good. When it’s dry, trim and drill for your new screw.

Like I say, easy and clean.

If you’re willing to make your own plugs, you can just buy Stew Mac’s screw extractor on its own. That will keep your costs down and you get the most useful part of the kit without shelling out for everything.

Incidentally, if you have an appropriately sized metal tube, it is possible to file some teeth into one end and use it as a makeshift cutter. I've done it in the past. It's not exactly the most durable tool you'll ever own but, for a single use, it can do the trick.

Using a Plug Cutter

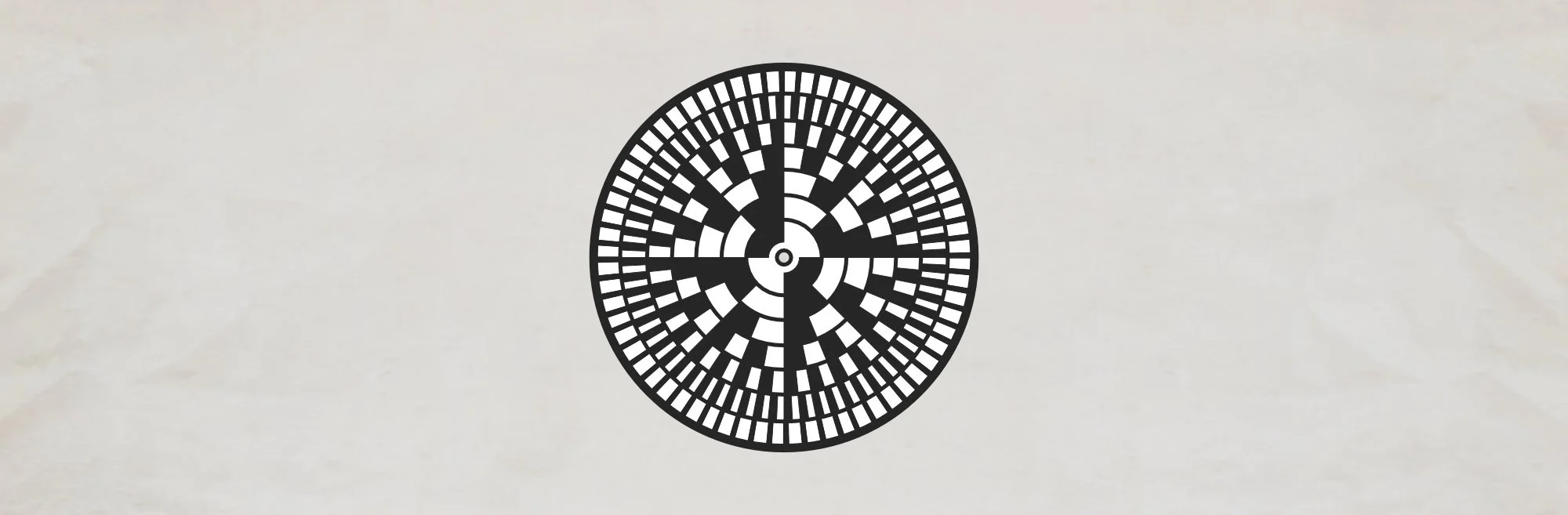

The extractor tool with the Stew Mac kit is fantastic for smaller screws like tuner screws but if you’ve something bigger you may have to step things up. A plug cutter can do the same job but the drawback is that its cutting ‘kerf’ is wider. By that, I mean, the material removed between the inside ‘plug’ measurement and the outside ‘hole’ measurement is larger. This means you end up with a bigger hole to fill and, potentially, to disguise with finish or whatever.

That’s obviously a drawback but it may sometimes be necessary.

Using a Drill Bit

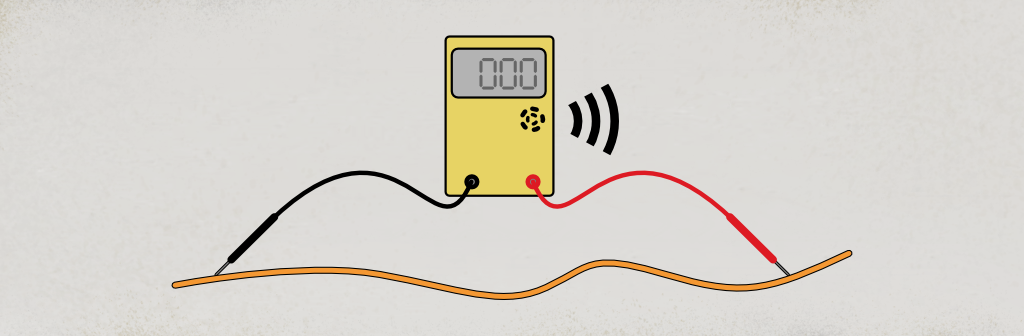

The cheapest solution. You can drill multiple small holes around the broken screw. This will (eventually) give you the same effect as having used the extractor or plug cutter. Be careful as it’s really easy for the drill bit to wander into a previous hole but, after a series of holes, you can usually wiggle the screw to work it out.

Follow up with a larger drill bit to clean up the messiness left by the multiple holes and to leave you with one, round hole. Then, make yourself an appropriate plug to fill it in.

If you’re careful, this method has the potential to give a smaller final hole than the plug cutter method. You can use a small drill bit and make multiple holes very close to the broken screw. With some patience, the hole you’re left with doesn’t have to be too much bigger than the screw.

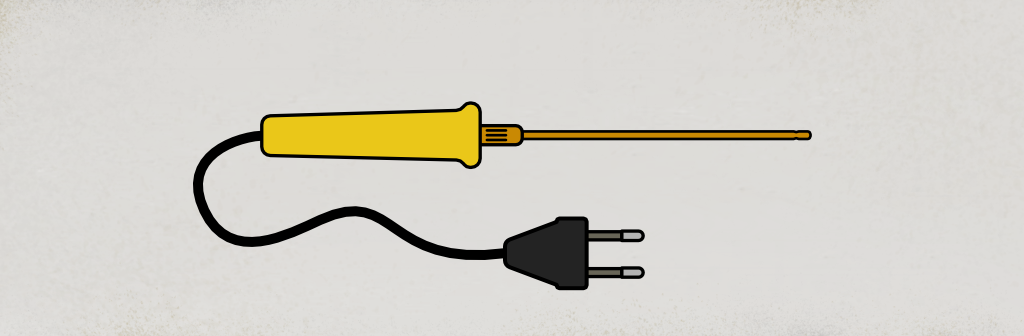

Drilling the Screw Itself

I’m reluctant to mention this but, if I don’t I’ll just get emails. It can (sometimes, in very, very limited circumstances) be possible to drill the screw itself.

This really isn’t the best method for working on a tapered screw that’s inserted in wood. It has it’s place but it works best for bolts and screws in harder materials like metal.

The idea is that you drill right down on the centre of the screw shaft and keep going until the screw has all but disintegrated. For the sorts of screws in your guitar, it’s generally a bad idea to even attempt. Bits can wander really easily, they can break really easily, and they can ruin your guitar really easily. I mention it for completeness but I don’t recommend you try it.

OK. That’s your lot. We’ve covered a lot on stuck screws and I hope that some information here is useful if you ever have to use it.

Actually, I hope you never have to use it. 😉

This article written by Gerry Hayes and first published at hazeguitars.com