Helpful Bone Thicknessing Tool (and a Life Lesson)

I’ve a somewhat niche little guitar repair tip to share this week but, since I also like to act like a kind of slightly presumptuous thought-philanthropist, I’m also going to pass on a life lesson.

Like I say, presumptuous.

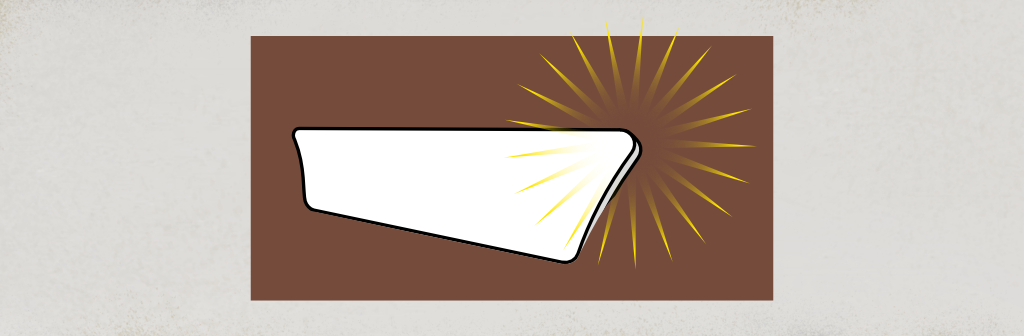

Anyway, the other day, I was making a bone saddle for an acoustic guitar. The most tedious part of making a saddle (or a nut, for that matter) is thicknessing it so it fits in the slot.

I use a series of sandpaper grits fixed to a flat granite sheet and getting the thickness right usually means a lot of sanding. When you’re dealing with already relatively thin part like a 3/32” (2.38mm) bone blank, holding it while rubbing it back and forth on sandpaper can be really annoying. It’s difficult to grip, you will sand your fingertips (although you stop noticing this after a few dozen), and it’s hard to apply a uniform pressure over its length.

It’s an annoying job that I’ve always disliked.

This time, half-way though the job, I stopped.

And I made the world’s simplest little tool to help me.

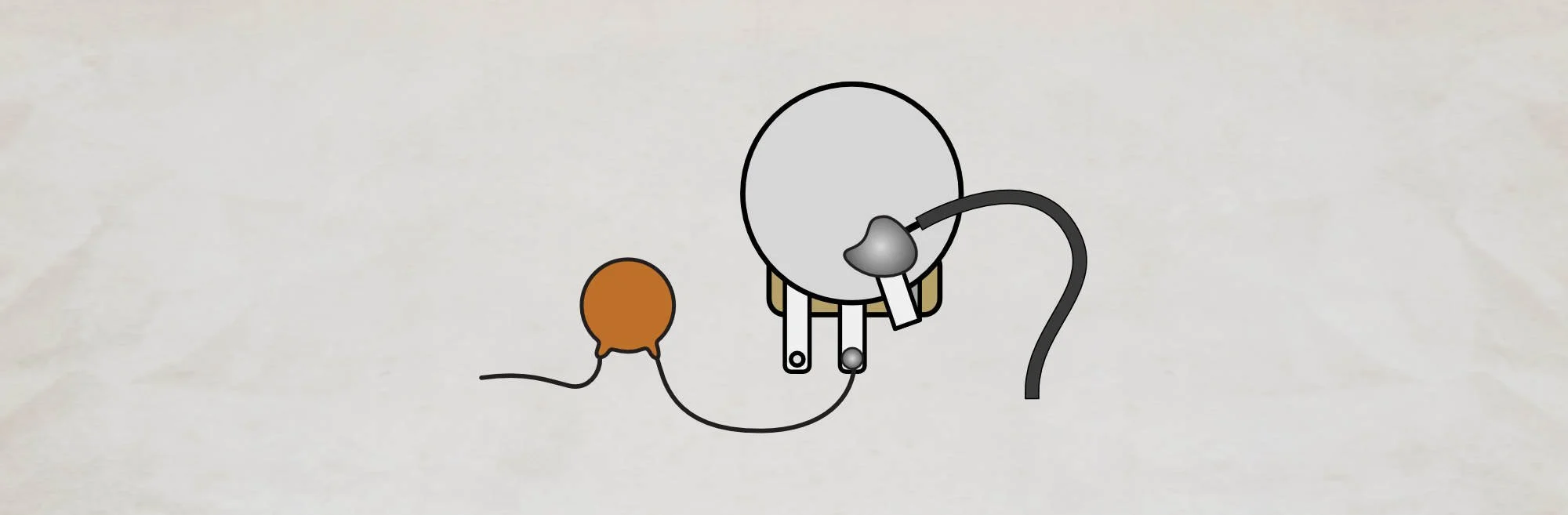

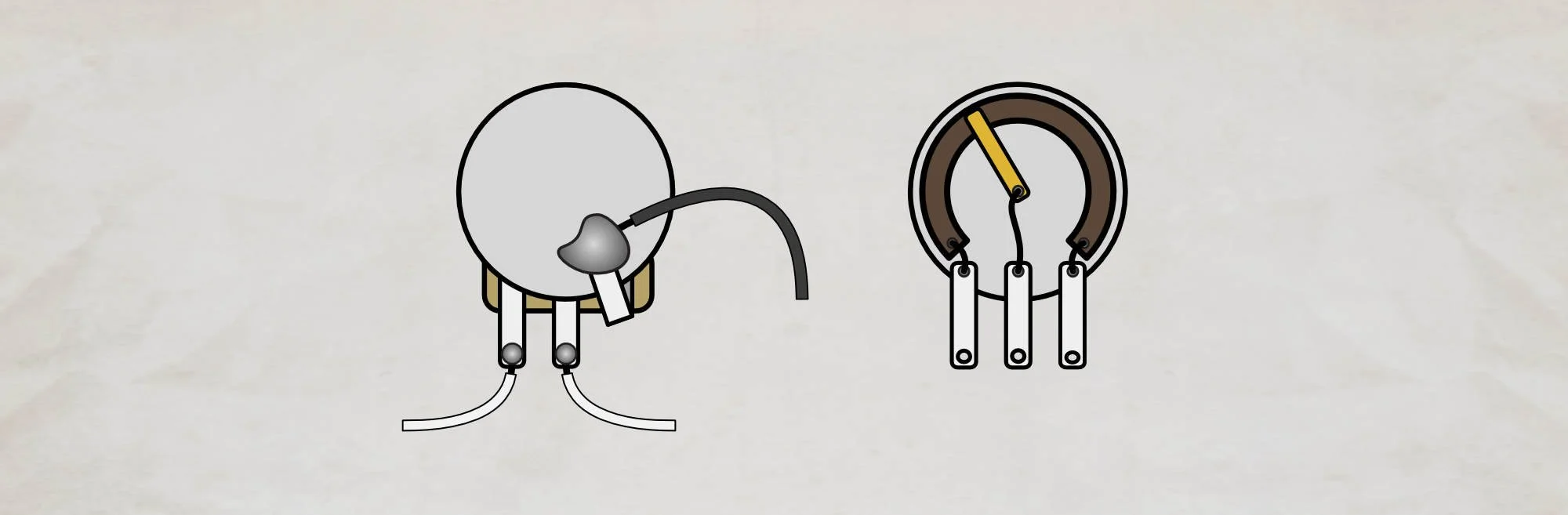

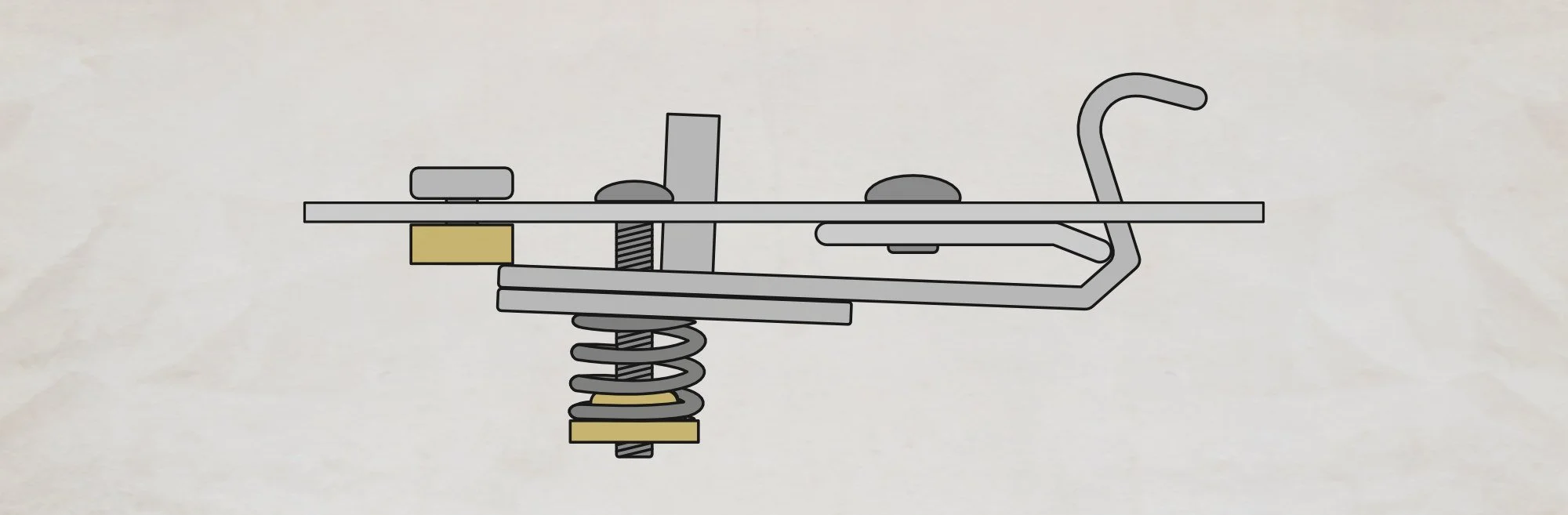

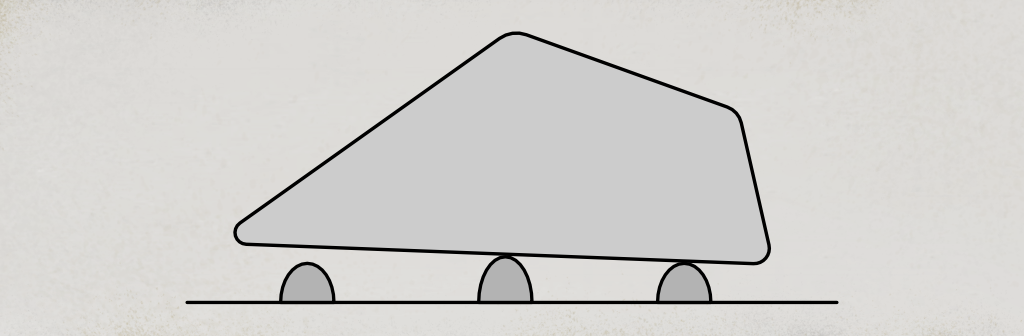

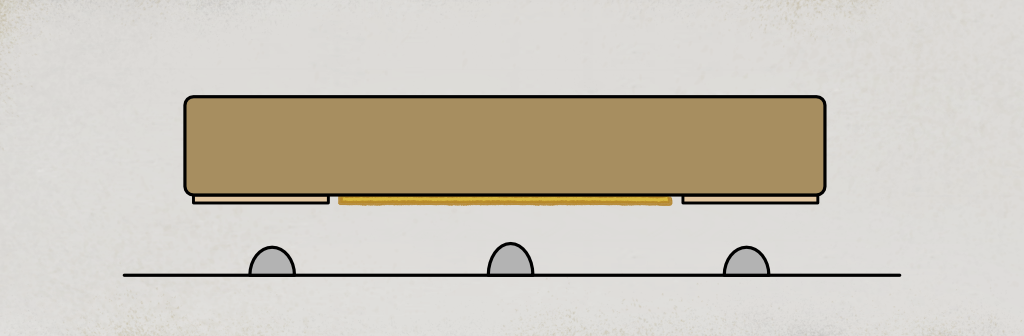

All this is, is a hunk of plexiglass that’s cut roughly to size. On the bottom, I ‘stacked’ two layers of acoustic guitar pickguard material. These bottom layers were glued around the edges of the plexiglass, leaving a recess in the middle for the bone saddle.

Each of these pickguard layers is .025” (.64mm) so, stacked, they make around .050” or 1.28mm which is more than enough to keep the saddle ‘captive’ while exposing enough of it to be sanded.

Eventually, the bottom layers will start to wear but it’s not a big deal. I can probably patch them but, if not, the whole thing took only a few minutes to make so I can just make another quickly and easily.

I lay down the bone blank, pop my new thicknessing tool-thing on top and can much more easily hold and sand the part. Like, much more easily.

This is an embarrassingly simple and unoriginal tool that took five minutes to make. It’s ugly and inelegant but it makes the job easier.

Every single time I’ve thicknessed a saddle or nut, I’ve thought to myself, “I really should make a tool for this.”

I knew it wouldn’t be a big deal to make. I knew it’d make my life easier but every time I thought that, I figured I’d just finish this particular job and then make the tool. I didn’t want interrupt what I was doing. So I soldiered on, swearing to myself as I did. When that job was finished, my mind just moved on to the next guitar and I never got around to actually doing this.

And the life lesson?

Something, something, procrastination. Something, something trees and forests.

It’s hard to take a minute to stick your head above the everyday cloud of chaos to see if there’s some way to improve things. And if there is a way towards something better, it’s hard to take the time to try it. We all get tied up in the flurry of NOW. There’s always work to be done and someone always wants it yesterday.

This silly little incident reminded me that it can be worth taking a few minutes out of NOW as an investment in the future.

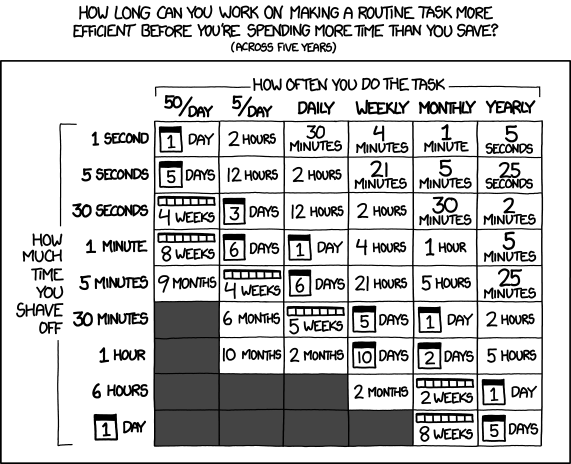

Of course, I definitely have to remind myself that I’ve sometimes gone down the path of building intricate, Rube Goldberg-style jigs and tools, spending hours making stuff that’ll only ever save me minutes over its lifetime. That work can have a place, of course, but it can also be the darker side of the time-investment thing I’ve described.

You: “So your great life lesson is to spend time now to improve stuff but don’t spend too much time now?”

Me: Nods sagely

You: Rolls eyes and walks away

Me: “Wait, wait. There was also the saddle sanding tool. Remember…?”

Anyway, thanks for indulging me this. I’m glad of the tiny kick in the butt I’ve gotten from it. I hope my enthusiasm here hasn’t been too annoying. I’ll try getting back to my usual, cynical self for next week.

P.S. Randall Munroe at xkcd has made a table to help determine if the time you invest in making something more efficient will pay off. It’s interesting (as is all of his stuff).

Image courtesy of xkcd, licensed under Creative Commons.

This article written by Gerry Hayes and first published at hazeguitars.com