How To Remove a Fender Guitar or Bass Nut

Thought it’d be useful to follow up on last week’s info regarding removing the nut from a Gibson guitar with some Fendery stuff. If you’re working on a Fender guitar or bass, the nut removal procedure is similar but has some differences that are very important.

If you’ve read the Gibson Nut post, there will be a little bit of repetition below. Sorry about that. I want this to be able to stand alone, though so bear with me and we’ll get to the differences in a sec.

Before removing a Fender-style nut

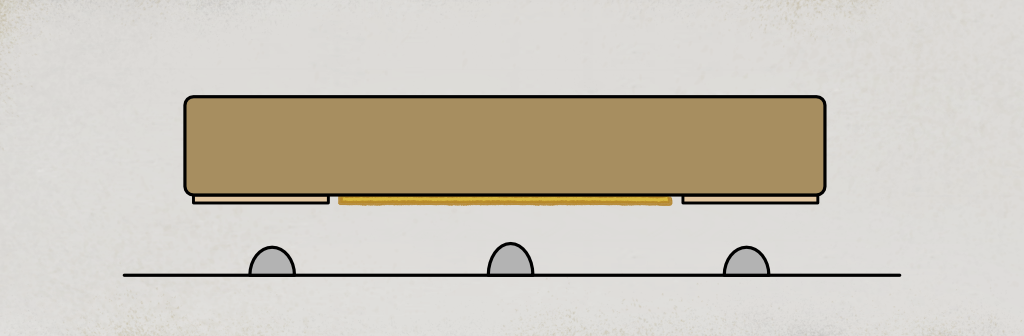

Very important… The nut is often installed in a neck before the finish is applied. So, for a rosewood fingerboard neck, you may well have some lacquer

- over the ends of the nut and

- along the headstock edge of the nut

If you’ve a maple fingerboard, remember that you’ll also have finish

- along the edge of the nut facing the frets/bridge.

Before you try to remove the nut, you need to address this lacquer or you’ll probably end up with some nasty chipping. Nobody wants that.

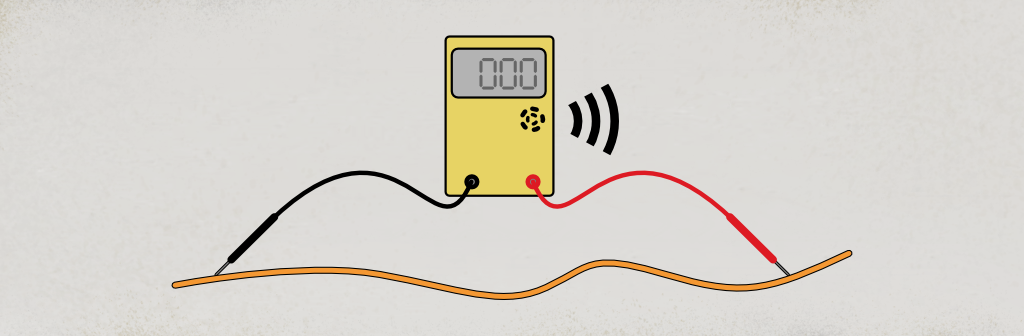

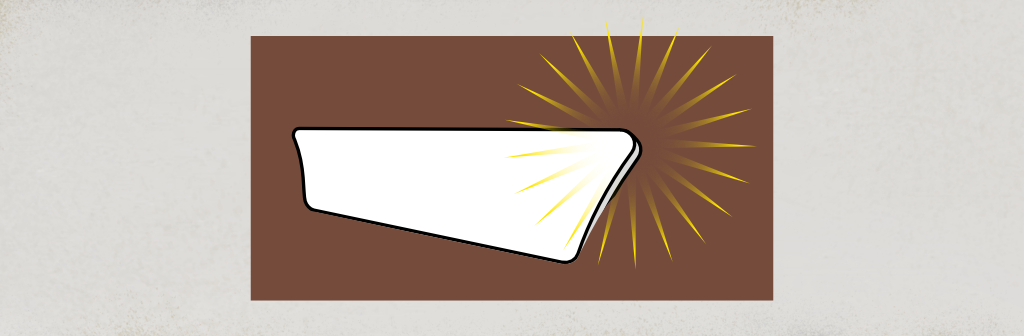

Scoring the lacquer

Use a very sharp knife — I use an exacto-style knife and a fresh blade — to gently score along the edges of the nut.

Gently is the right word here. At different times, Fender have sprayed a LOT of lacquer on their necks so you really have to be careful. Don’t try to cut all the way through in one go or you’ll chip the finish. Go slowly and carefully and make a number of shallow cuts.

Slower, shallow cuts are much easier to control too. It’s less likely that the blade will wander off on its own path and leave you with a scratch.

Most of the time, you won’t need to go all the way though. Making a good score-line should introduce a fault line into the finish and encourage it to break there if it’s going to break.

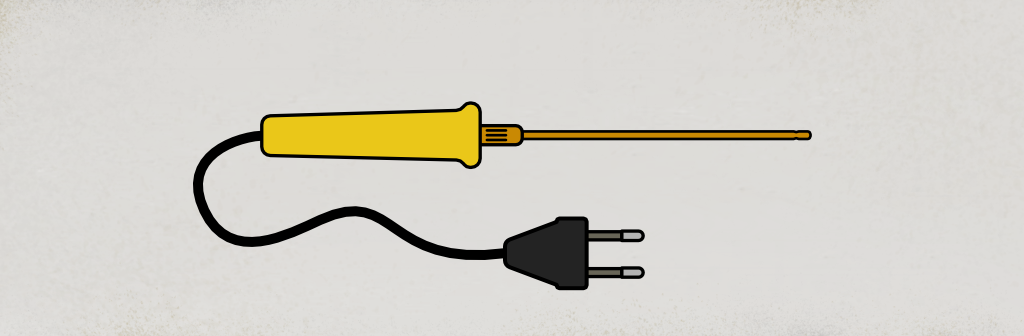

Removing the Fender nut

Now, in the advice for Gibson-style nut removal, I recommended butting a wood block against the nut face and tapping it out with a hammer.

I DO NOT recommend doing this with a Fender-style nut.

Gibson-style nuts are installed at the end of the fingerboard whereas Fender nuts are installed in a slot near the end of the fingerboard. A hammer blow to a Fender nut’s face risks knocking loose that hunk of fingerboard behind the nut.

Don’t ask how I know this.

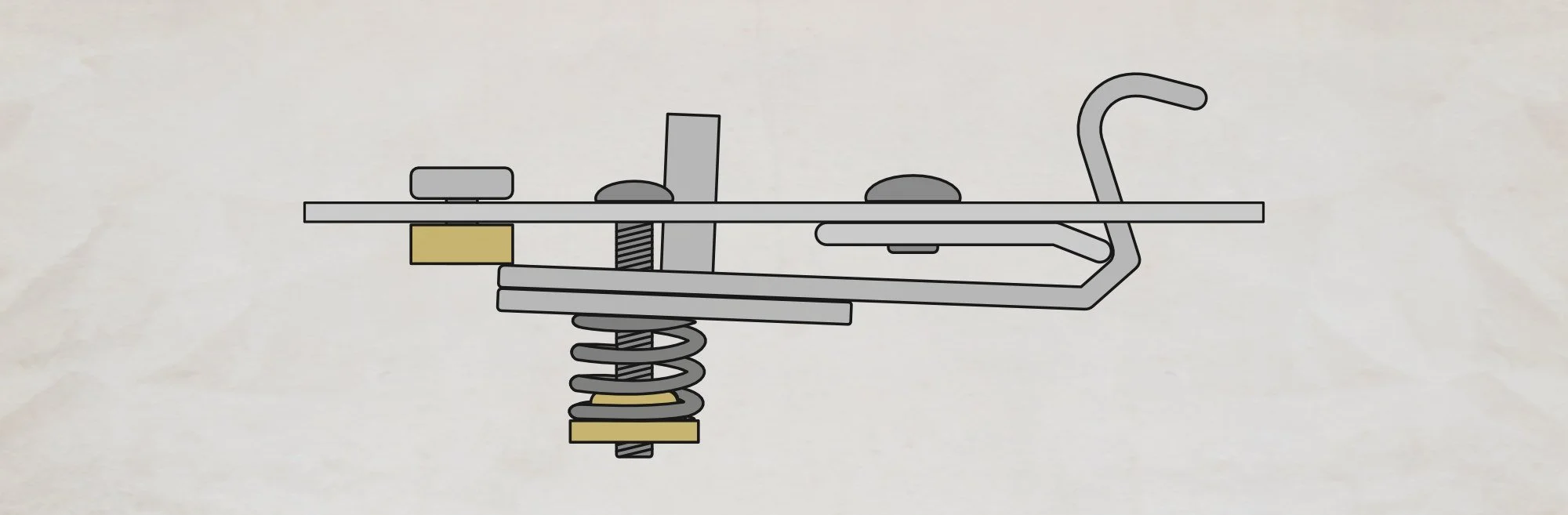

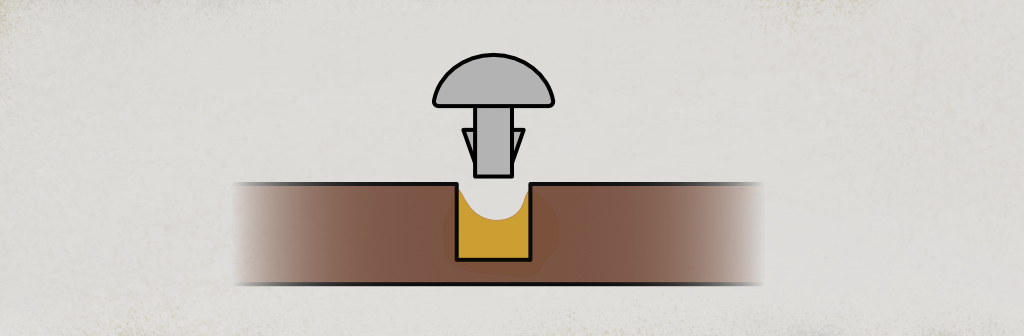

What you’ll actually want to do is to grip the nut with pincers (ideally).

Then, carefully wiggle back and forth as you lift.

Take it easy here. Again, you’re not trying to yank this out in one fell swoop. Gradual wiggling and gradual lifting. It’s a good idea to grip slightly higher up the nut with the pincers. That’ll prevent you marring the fingerboard as you wiggle.

You should start to loosen stuff pretty quickly. Keep an eye on the finish as things begin to move.

It’s not that unusual for the nut to break as you’re extracting it — they’re narrow and somewhat brittle. If you’re replacing the nut (which I assume you are if you’re removing it) that’s not a big deal. If you want to reuse the nut, be even more careful and keep your fingers crossed.

When the nut (or pieces) are safely out, you can clean up the slot. It’s more tricky to clean glue out of these slots than the wider, more accessible Gibson-style. Narrow files or, ideally, some micro chisels will be very helpful. Stew Mac have some decent chisels and you’ll find a pretty big selection on eBay (affiliate link).

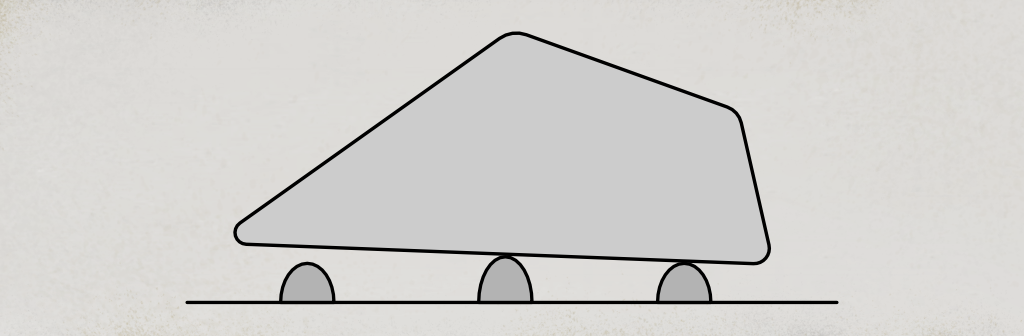

Finish ramp

You’ll often have a ramp, or lip, of finish along the long edges of the nut. Be cautious of that when you’re working on the slot and fitting the new nut. Remember, finish chips easily. A little very (oh, so very) gentle sanding can widen the finish ramp either side of the slot so the new nut slides past the brittle lacquer more easily.

So. Fender nut removal… Check.

This article written by Gerry Hayes and first published at hazeguitars.com