Feudin' Banjos

Taking a look at a de-laminating banjo this week. I don't tend to get a lot of banjos through the workshop but, this being Ireland, one shows up every now and then. I write about banjos far less than I see them but, the repair on this one is something I thought you might find interesting.

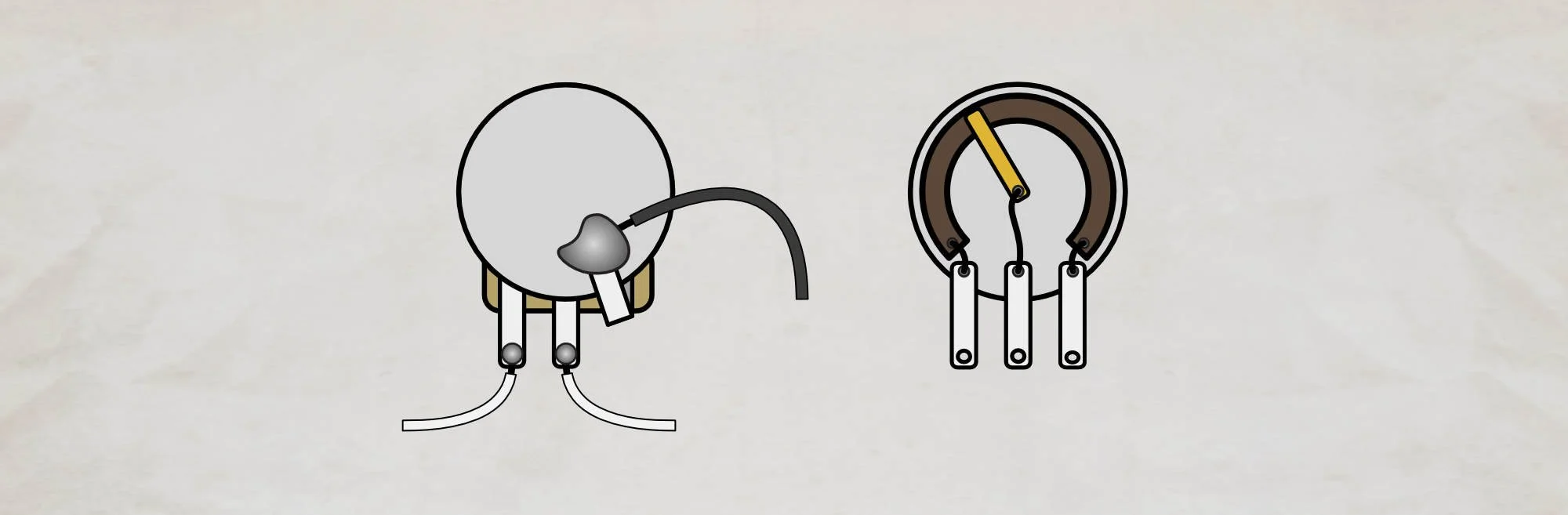

We won’t dig too much into banjo anatomy as it’s more involved than assembling a 12-string Floyd Rose bridge while blindfolded. However, the part that tends to ‘house’ everything on a banjo body is a wooden rim (sometimes called a pot). It's a ring or hoop of wood.

This rim is frequently made from a number of pieces of wood laminated on top of each other (easier to bend thinner pieces). Sometimes, the glue holding the laminations together can give up a little over time. You might have seen older (or cheaper) plywood begin to separate into layers — similar thing.

This banjo is a lovely old Orpheum that’s coming up on its hundredth birthday and there’s some de-lamination occurring. It’s not bad yet but the owner wants to nip it in the bud.

I don’t have a ‘before’ photo. Sorry. We’ll have to rely on a description. In the top edge of the rim (the part normally hidden by the banjo head, there was a gap that ran in a circle, most of the way around the rim, with interruptions here and there. The opposite edge was fine so I know the problem doesn't extend all the way through.

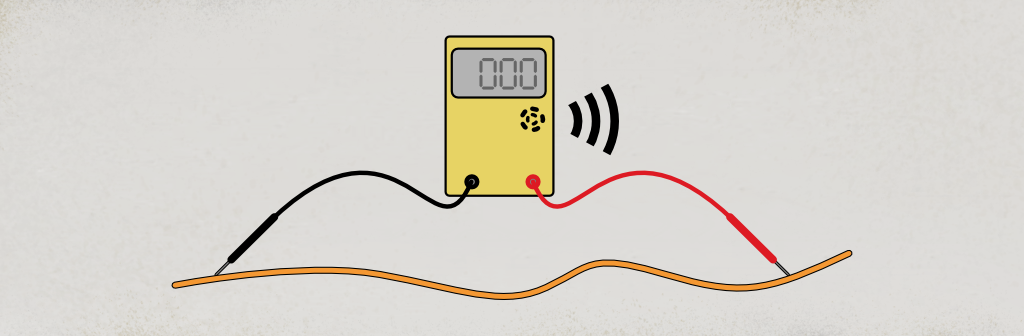

The problem with trying to repair this is ensuring this gap is secured to its full depth. The circular crack wasn’t wide enough that I could work some glue deep inside and it wasn't easily possibly to force it open. I considered low-viscosity superglue but didn’t feel like I’d get the penetration needed before it cured, blocking further applications.

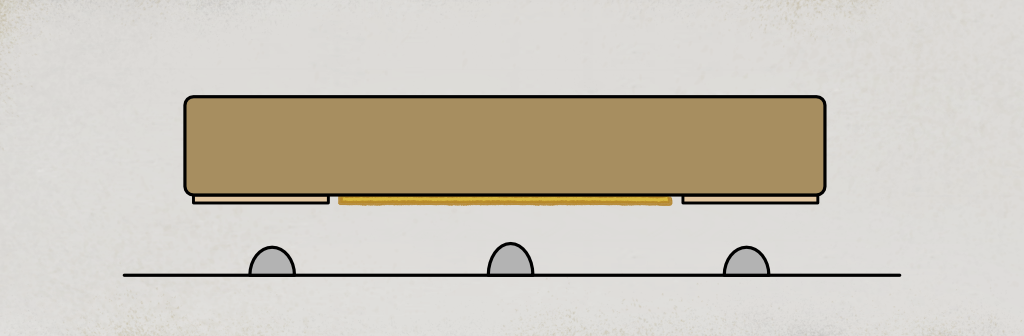

After a little thought, what I settled on was to rout a narrow channel around the rim edge. I’d centre the channel over the de-laminating gap. Doing this would allow me to inspect how deeply the separation was running. Also, I could then fill or inlay some fresh wood into the channel to help keep things together.

Let’s look at the routing first.

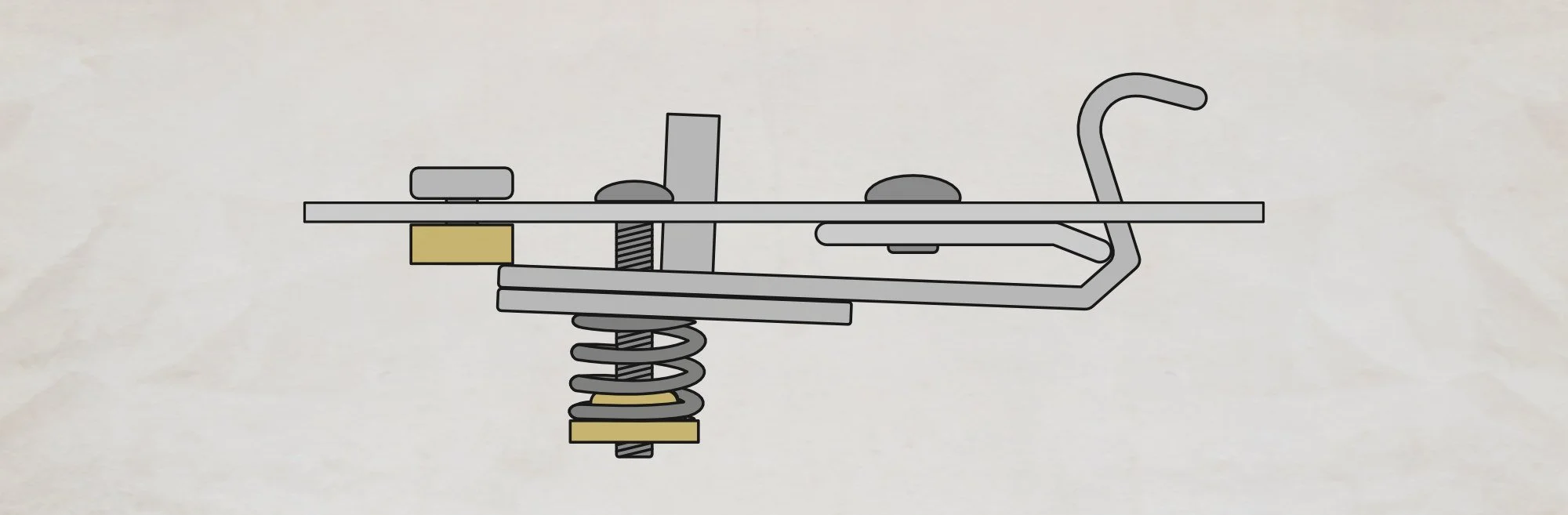

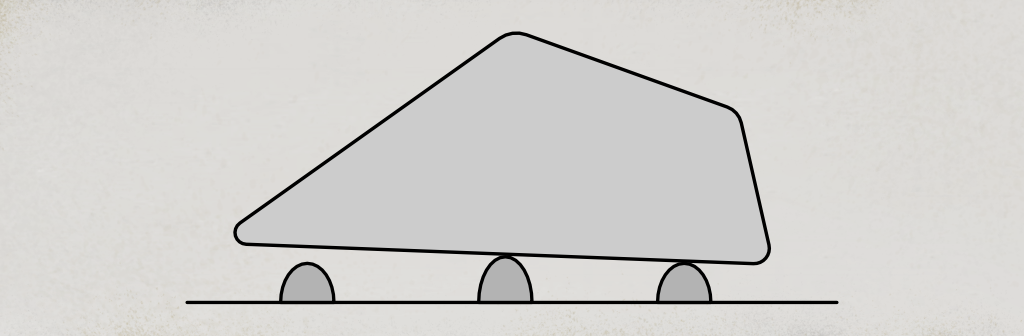

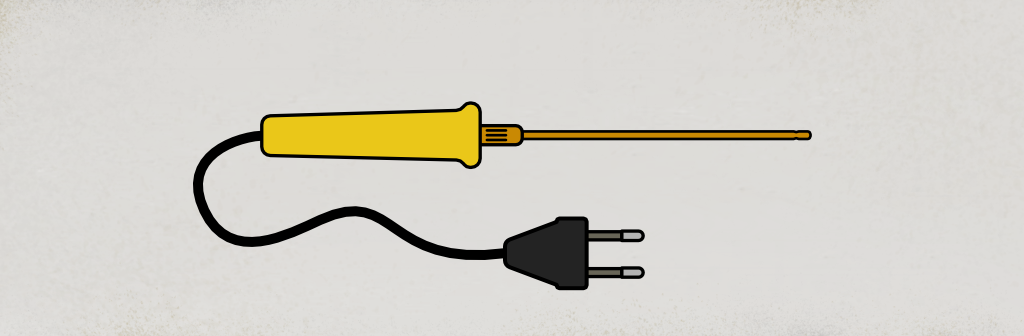

I used my Dremel-type tool in its router base fitting. To help keep things aligned, I made a little guide block. In an offcut of ash, I marked a pencil line following the inside of the banjo rim. It was easy to cut along this and double-stick tape it to the router base. This will keep the router where I want it as I move it around the top of the rim.

I made a few shallow passes with a 1/8” (3mm) downcut router bit, inspecting things after each circuit. After routing down about 4mm, I couldn’t see any more evidence of de-lamination. To be safe, I routed another 1mm or so deeper. All seemed well. Good.

Now to back fill the channel.

It is certainly possible to thickness a piece of hardwood and steam it into a perfectly matching circle but, damn, that’s a lot of difficult and precise work that doesn't add any real value to this repair. The tone's not going to be impacted by this.

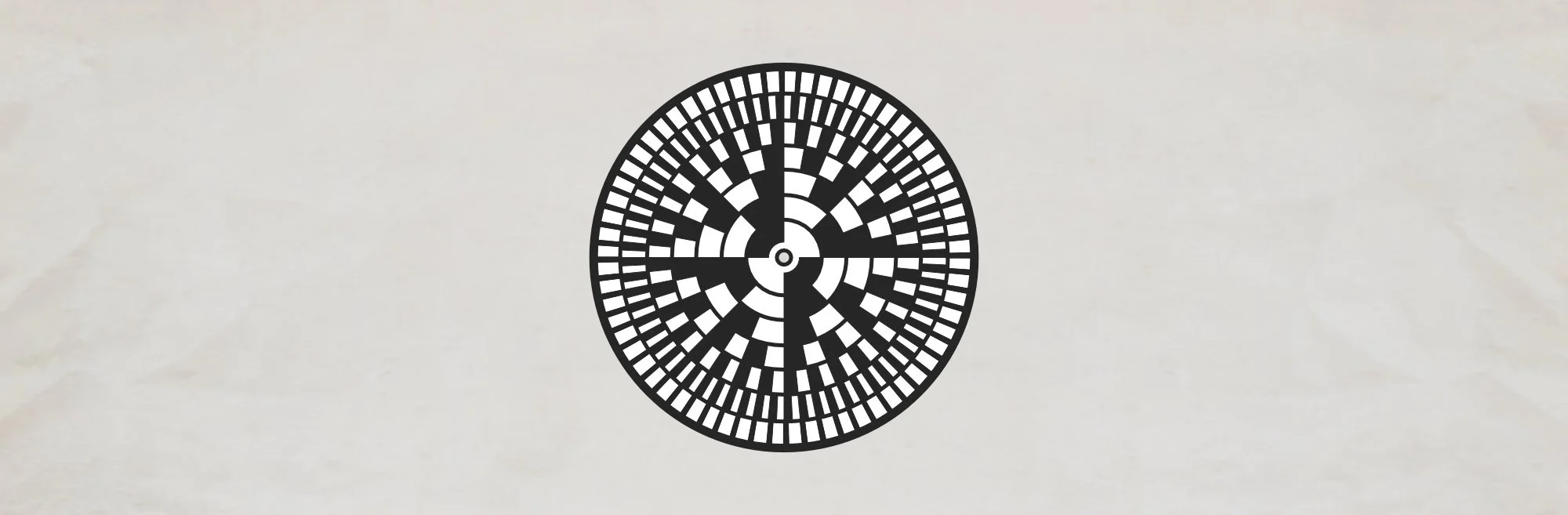

I decided to make my own plywood.

Using strips of edge banding (the doll’s house floorboards I mentioned ages ago), I was able to get a perfect fit in my channel by stacking five strips together. I decided to go the messy route and use epoxy for this job. I donned the rubber gloves, mixed up a heap of epoxy, and brushed it onto each banding strip. When I had them up to thickness, I got really gooey by brushing the outsides and pushing them into the routed channel (I masked off a lot of stuff beforehand).

These strips could easily be bent to conform to the circular shape. I left them protruding from the slot and, after they'd spent a day curing, I trimmed them down flush with a sharp chisel. I did turn to superglue here. I used just a little low-viscosity glue to wick into one or two small pin-holes caused by a bubble in the epoxy and a little regular stuff just to build any minor dips around my channel up to flush-level.

A little sanding to clean things up and then it was just a matter of applying some finish. And, since the existing finish in this area had been—very obviously—brushed on, I did the same. No need to spray anything.

So, I hope this digression into non-guitar instruments has been interesting. Will get back to guitary stuff (or at least my ranting about guitar-related stuff) next time. 😉

P.S. Pedantic nerd bit: The title of this email refers to a track many people know as Dueling Banjos. The original was written twenty-odd years before it ended up in the movie, Deliverance (it was tweaked a bit for the movie). The original actually consisted of a pair of banjos rather than a guitar and banjo. Now you can impress your friends with banjo/movie trivia.

P.P.S. As a bonus nerd link, I found Glen Campbell and Carl Jackson having fun with Dueling Banjos while looking for that last link.

This article written by Gerry Hayes and first published at hazeguitars.com