How to Install 'Pinned' Tuners

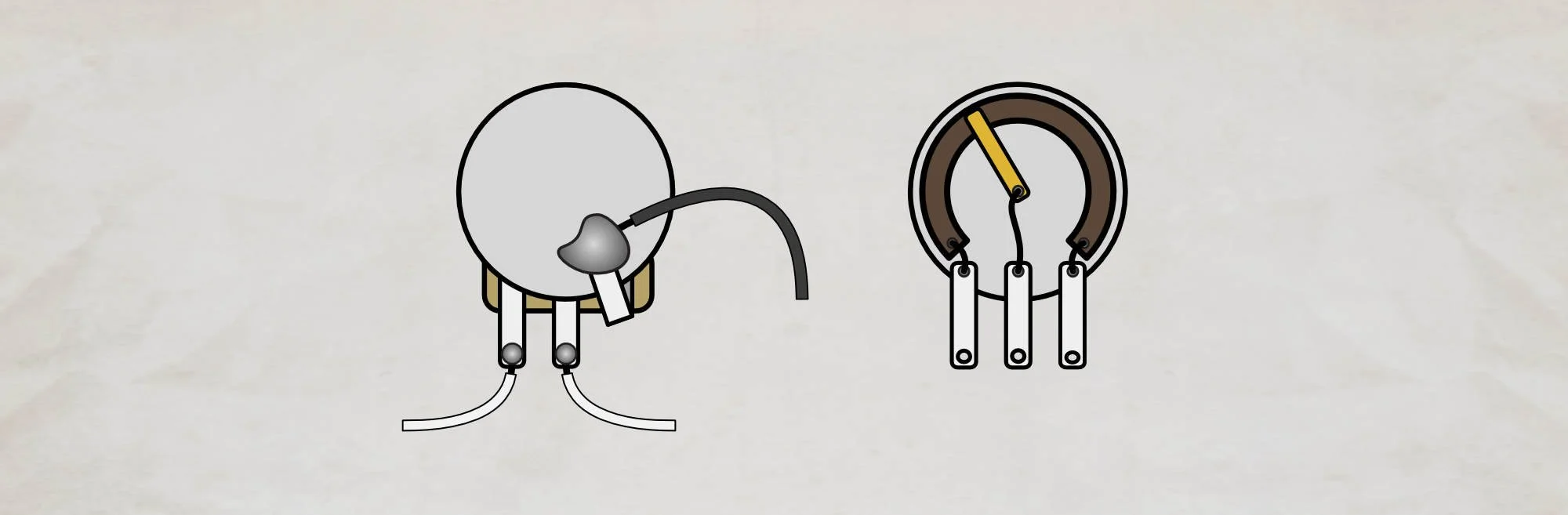

Last time I briefly mentioned that some modern tuners don’t have any screws on the rear. Instead, these tuners have one of more pins that fit a corresponding hole on the rear of the headstock.

This lead to a number of questions as to why that might be and whether there are any benefits.

First the why.

Why do some tuners use pins instead of screws?

Let’s consider the role of the screws.

In vintage-style tuners, the screws serve to hold the tuner onto the headstock. That’s an important job. The tuner post protrudes out a bushing at the front but there are no fixings there. The screws around the back do that job.

On modern tuners, the bushing at the front is threaded. It passes through the headstock and screws into the body of the tuner. As it’s tightened, it holds the tuner in place pretty firmly. But not quite firmly enough…

The screw around the back of a modern tuner mainly serves to prevent the whole tuner body from rotating as it’s pulled by string tension. That’s really its only job.

So, with this in mind, instead of a screw, you could just have a protrusion on the tuner body. This protrusion would insert into a corresponding hollow on the back of the headstock. This would serve exactly the same purpose of ‘keying’ the tuner body in place and preventing it from rotating.

So what are the benefits of pinned tuners?

I suspect the biggest reason for these is that they’re faster to install in a factory setting. If the neck’s being cut by CNC, accurate holes can be cut to accept the pins and the tuners can be tightened from the front quite quickly. You skip the assembly step where a worker screws in six tiny and fiddly screws – that seems like it’d be a decent time-saving.

A side-benefit is that, much of the time, you can swap on a new set of tuners and not have any visible holes in the headstock from the old ones. Of course this depends on the size and shape of the new tuners but, you’ll often get lucky.

And, if you’re happy to install tuners from the same manufacturer (or an OEM version) you can retrofit replacements really easily. It’s still advised you do a little research to be absolutely certain you get the same pin layout.

There is a drawback, however. If you’re installing pined tuners onto a guitar that hasn’t had them before, these are trickier to fit for the DIYer. It’s easy to mark the position of a screw hole but, when you have pins hidden by the tuner body, things are more difficult.

How To Install Pinned Tuners

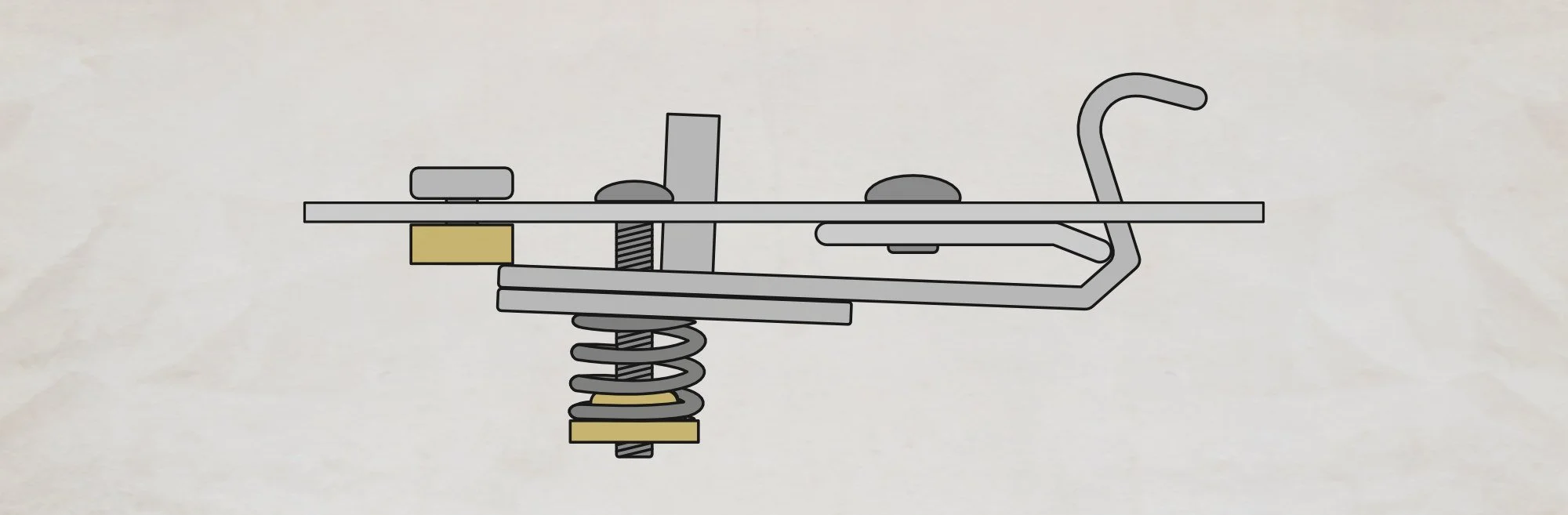

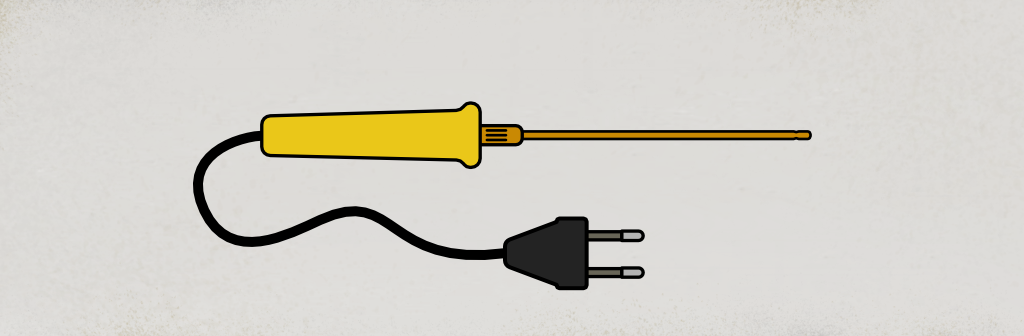

Well, as you might expect, you can buy a tuner pin drill jig and, if you’re going to be doing this job more than a couple of times, I recommend you do so. It makes a fiddly job fast and accurate and it’s got a number of holes for different tuner pin configurations. It’s not cheap, however, so we’ll talk about an alternative in a minute.

Installing pinned tuners with a jig

Using the jig is pretty self-explanatory. Install it around the back (double-check it’s pointing the right way), screw on the centering nut from the front of the headstock and line it up. On a 6-a-side headstock, you can use a ruler at each end of the jig to measure the same distance from the headstock edge. There’s also a little notch in the short edge of the jig that you can line up by eye with the next tuner hole along (this is surprisingly accurate but measure if you want to be certain).

When you’re aligned, tighten up the nut and drill your holes. The jig has the added benefit of keeping the holes nicely perpendicular to the headstock.

For 3-a-side headstocks, the process is a little less exact. It’s not so straightforward to measure and align the jig and I usually just eyeball it.

Installing pinned tuners without a jig

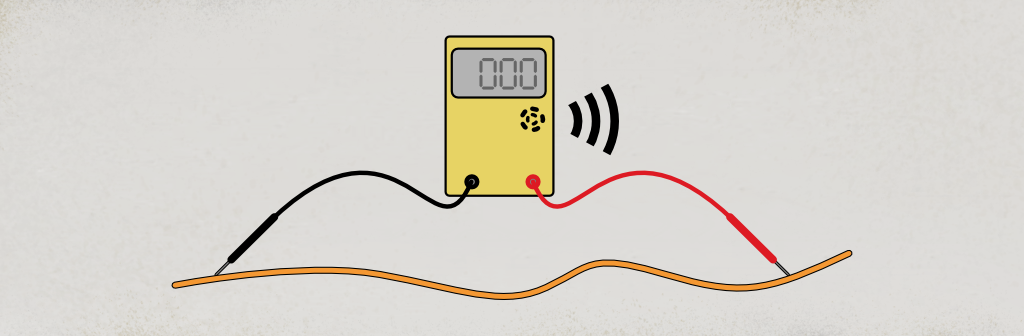

It's possible to use the alignment pins to mark their own positions on the back of the headstock. It’s just not easy.

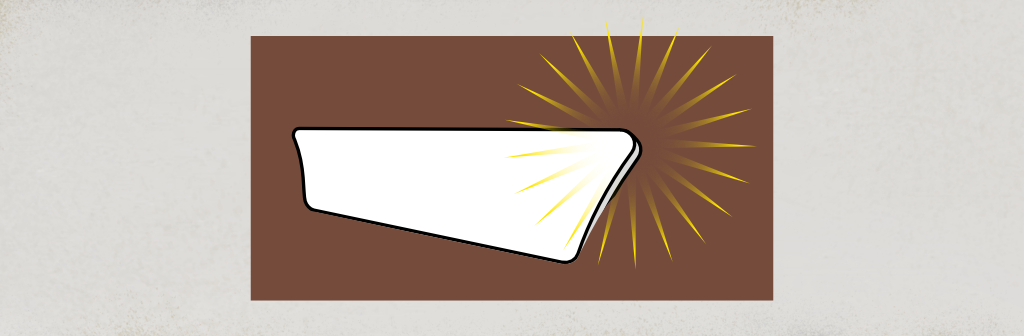

If you have access to some copper tape (the sort used for shielding), stick a piece in the area where the pins will go and insert your tuner. Screw on the bushing and nut from the front (just barely finger tight) and line up the tuner at the back. When you’re happy with the position, press hard on the back of tuner and then unscrew and remove it.

If all’s gone well, you should have a dimple corresponding with each pin position. Use a sharp scribe to poke through the centre of each dimple to make a more conspicuous mark on the headstock itself. Repeat for the other tuners and, when you’ve got your locations, you can drill away.

Copper tape is soft and takes the dimple marks (relatively) well. If you can’t get it, you can try using a couple of layers of masking tape for the same process.

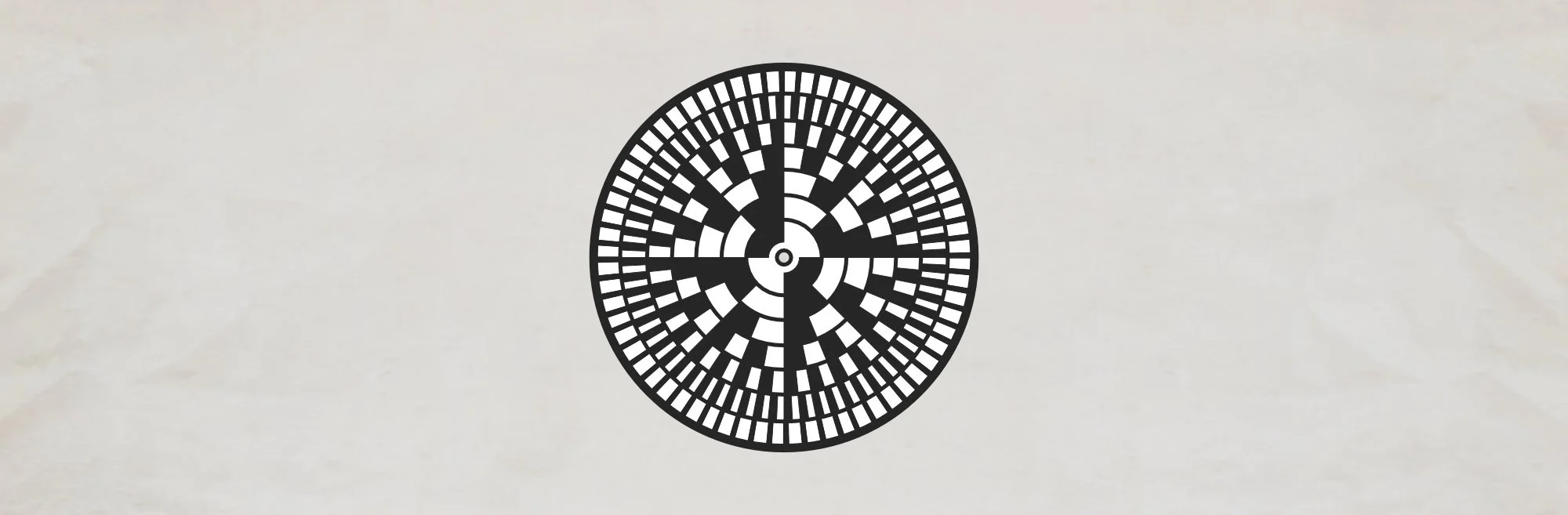

A note on drilling

Drill bit size is very important. These pins are all that’s preventing your tuners rotating under string tension so don’t drill too big a hole. Measure the pin size and be as exact as possible.

Obviously, you’ll want to mark a depth stop on your drill bit too. Use a little masking tape to ensure you don’t drill too deep and poke out the front of the headstock.

The drilling jig keeps the bit perpendicular to the headstock. If you’re not using a jig, try your best to drill at right angles to the back of the headstock. It helps keep the tuners securely in position.

Lastly, if you're drilling through finish, after you've done, it might help to use a countersink to ‘widen’ the holes just to the depth of the finish. This means the pins won’t press any finish as they seat, reducing the risks of any cracking. You can also use a slightly larger drill bit to widen the hole at the finish level but be careful it doesn’t ‘grab’ and drill too deeply.

And that’s it. Assuming you’ve located and drilled all your holes well and at the right size, fitting the tuners should be a doddle. tighten up the nuts from the front using a spanner/wrench or an appropriate hex socket. Don’t use pliers unless you’re happy to mar the plating on the nuts.

This article written by Gerry Hayes and first published at hazeguitars.com