How to replace modern tuners with vintage-style Part 2

Last week we began talking about how to swap in vintage-style tuners for modern units. And, to be honest, that discussion covered the most troublesome part of the process: dealing with the size-difference between the two tuner styles. Turns out it’s pretty easy if you know how.

And the same goes for this next part. Once we’re equipped with the conversion bushings we need, getting these tuners installed is pretty straightforward.

Remove the existing tuners

Uninstalling modern tuners is a doddle. Use a small adjustable-wrench or shifting-spanner to loosen the hex nuts on the face of the headstock. Obviously a box-wrench or a socket would also work but try to avoid using pliers as they’ll probably mar the nut.

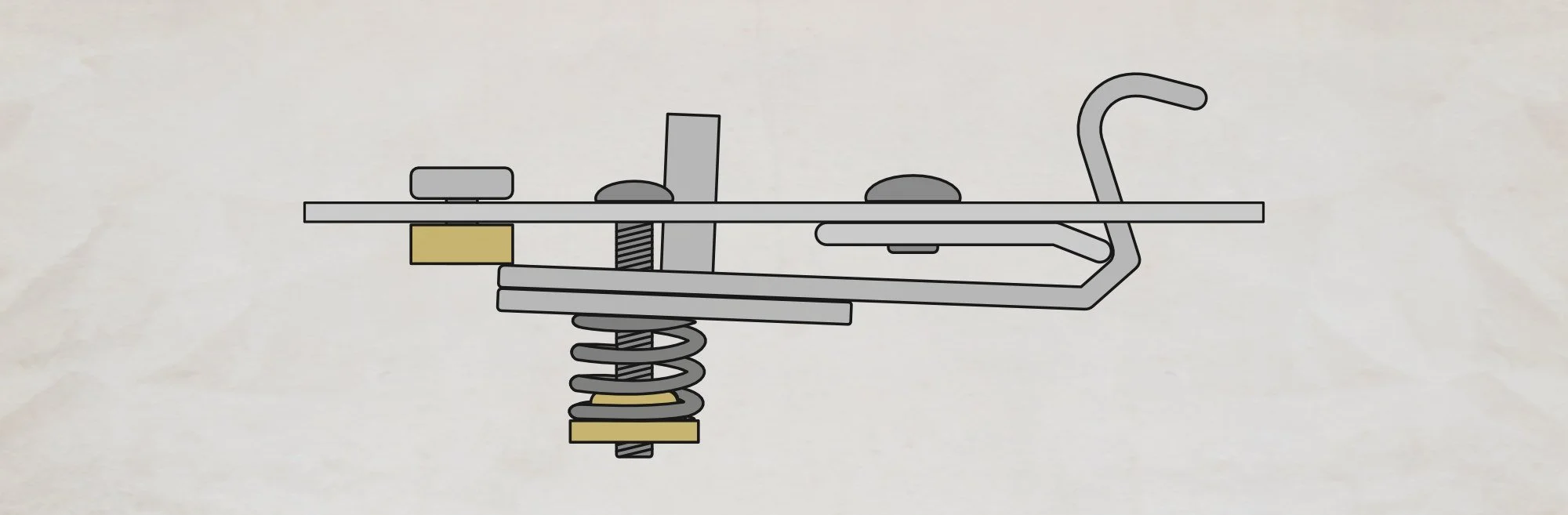

Once the nuts are loose flip the guitar over. You’ll probably find each tuner has a single screw securing it at the rear. Use a screwdriver to remove those. Note: Some tuners don’t have any screws at the back – instead they have one or more pins that insert into holes in the headstock under the tuner body.

Once that’s done, you can remove the tuners.

Deal With the Finish

You may not have to worry about this but, if there’s a finish – especially a thick finish – on the front of the headstock, you might think twice about shoving press-fit bushings into it. The pressure of the bushing installation could crack the finish.

You can use a reamer or countersink bit to ‘excavate’ some of the finish around the face-side of the tuner holes. You don’t need to go nuts here but taking the edge off the finish around the holes might be a good idea.

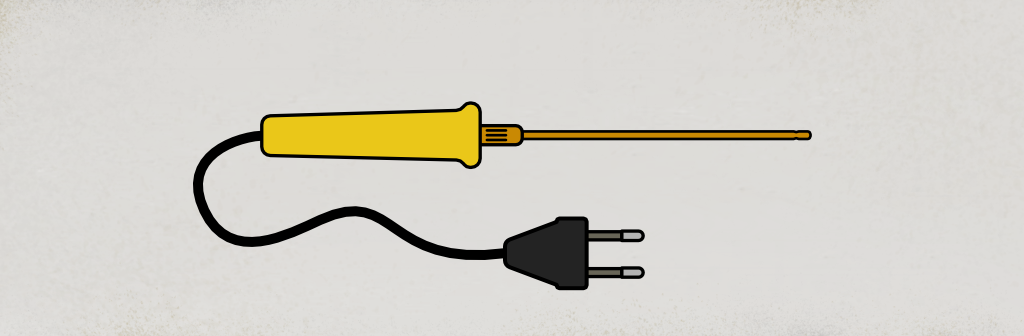

The other option (and it’s a good alternative if you’re careful) is to heat the bushing with the tip of a soldering iron. Seat the bushing so it grips and stays put, heat it up, and press it home. The heat softens the finish around it so it won’t crack so easily. This works best with the clamping method described below. The bushing doesn’t need to be glowing red-hot or anything but you will need a powerful soldering iron for this. You’re probably wasting your time with irons less than around 40 watts.

Fit the Conversion Bushings

Actually, before I get to this, I have to remind you there are two different sizes of conversion bushing: 10mm and 10.5mm. The latter is required for more modern Fenders but (no matter what your guitar) it’s a good idea to remove a single tuner and check the hole diameter before you order your bushings. Makes sense to make sure.

Assuming, you've got the correctly sized bushing you can press it into the holes in the front of the headstock. Usually this requires more pressure than your thumb can muster so you’ll need an alternative. You can buy a fancy-pants tool for installing bushings (I’ll get one eventually but I’m too cheap at the moment) but most of you will choose one of the following methods:

Tapping bushings in with a hammer

This is the most obvious route for the DIYer but it’s not the most ideal. Still, though, I realise it’s necessarily the default for many.

Place the rear of the headstock on something solid and flat (if you’ve an angled headstock, this will mean some contortions or maybe having a friend hold the guitar off the edge of a table or worktop). Add a little padding behind the headstock to protect it – ideally a sheet of cork or a few thickness of cardboard (not corrugated).

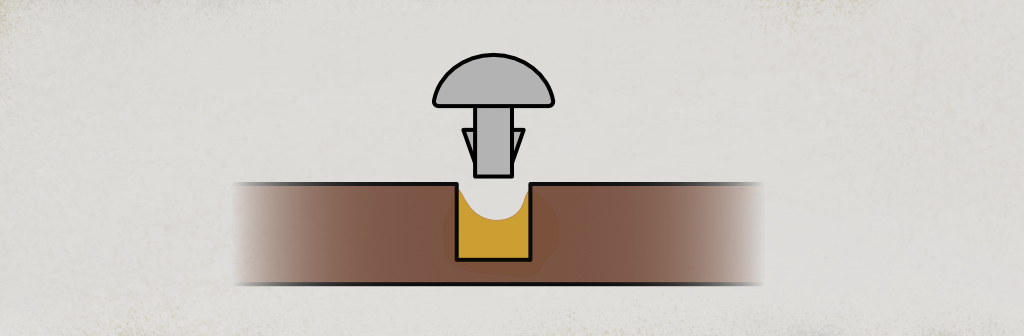

Insert the bushing and (gently) tap it home. If it goes in easily, great. If it needs a little more persuasion, use a wooden block to protect the bushing from hammer blows (beware that the edges of the block don’t damage the headstock face). If it seems like serious persuasion is required, see below and don’t force it.

Pressing bushings in with a clamp

If you have a clamp handy, you’ll be able to exercise a little more control in bushing installation. Insert the bushing and carefully close the clamp over it to seat it in its hole.

Obviously, use a caul to between the clamp and the rear of the headstock to protect the guitar.

Again, don’t force anything.

If the bushing hole is too tight

Danger, danger. If the bushing doesn't seat completely with relative ease, don’t force it. It’s not impossible to split the headstock completely if you do. That’s rare but not unheard-of.

If it seems like you’ll need to press or hammer more than you’re comfortable with, stop. Try to enlarge the hole slightly so it’s better able to accept the bushing.

A reamer is a good way to do this but, again most readers won’t have easy access to this. So, do it the DIY way. Wrap a little sandpaper around a pencil and carefully and gradually sand around the perimeter of the hole. Keep checking the bushing often so you don’t go too far.

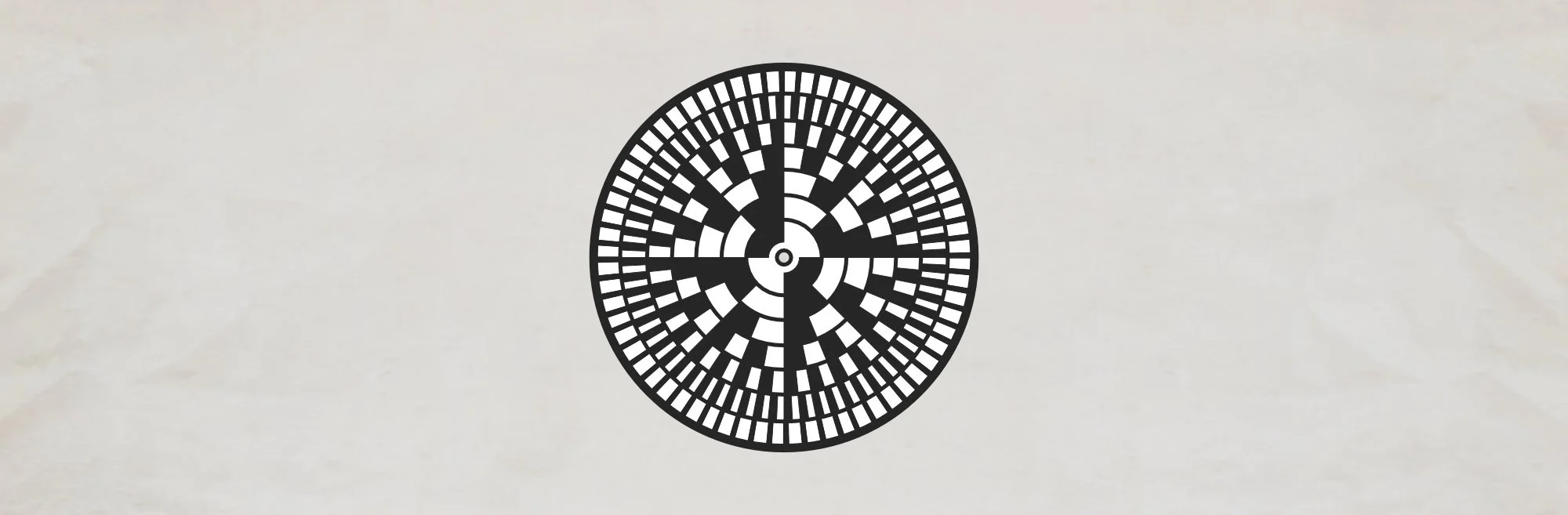

Laying Out New Tuners

With the bushings installed, you can turn over your guitar and pop your tuners in the appropriate places. Since you want to accurately mark the locations for screws, you need the tuners sitting nicely in their proper positions.

For six-a-side headstocks, a good tip is to use a ruler to line up the bottoms of the tuners. I pressed this steel rule against the tuners to nudge them into position and then clipped the ruler to the headstock. This keeps them relatively well placed but they can still move about so be careful as you mark the screw-hole locations.

If your tuners aren’t all nicely in line, you’ll just have to eyeball it and hold each separately as you mark out.

Use a pencil or a scribe (or even a long, sharp nail) to mark the position of each screw. Then, take the tuners off again and get your drill.

Drilling For New Tuners

Getting a drill bit that’s the right size for the screws is easy. You want a bit that is as big as the solid ‘shaft’ of the screw but not as big as the outer edges of the threads. Hold the bit against the screw and compare their sizes.

Using too big a drill bit means there’s not enough wood left for the screw to cut its thread. Too small a bit means the screw is too tight in the hole and – especially with such small screws – you risk shearing off the head. Don't force these screws, buuuut… in harder wood like maple, it can often be useful to lubricate the screw a little to help it make its way in. A little candle wax in the threads (just give the screw a scrape of the side of a candle) can be a big help.

Bit size determined, now you can mark the depth. This time, look at the screw length and use a little piece of tape to mark a stop-point on the bit. This means you won’t drill deeper than the length of the screw (and you won’t drill right out face of the headstock).

Drill your holes. Afterwards, as for the bushings, it can be useful to countersink very slightly around the screw holes to prevent the screws cracking the finish.

The rest is easy. Fit the tuners. Screw in the screws. String it up and play.

Depending on the design of your old and new tuners, you may have some unwanted screw-holes from the originals. You can back-fill these relatively easily but this is already a long one so we’ll look at that another day.

That’s it. Vintage vibes all the way.

This article written by Gerry Hayes and first published at hazeguitars.com