Sticky Tuners II: Sealed Units

Last time we talked about cleaning and (frugally) lubricating some standard, open tuning gears. I'll just stress that 'frugal' part here and remind you that you don't want puddles of oil around your tuners. Treat your lubricant like it's something incredibly expensive—printer ink, maybe.

So what happens if we're dealing with sticking tuners but we can't get at the gears? What if the tuners are sealed?

Well, to be honest, these things hardly ever give trouble. If one seems to be difficult to turn, try removing strings and taking the tuner off the headstock to see if it's catching up on something external.

If not, well, I suppose we should try do something about it.

Cleaning and lubricating covered tuners

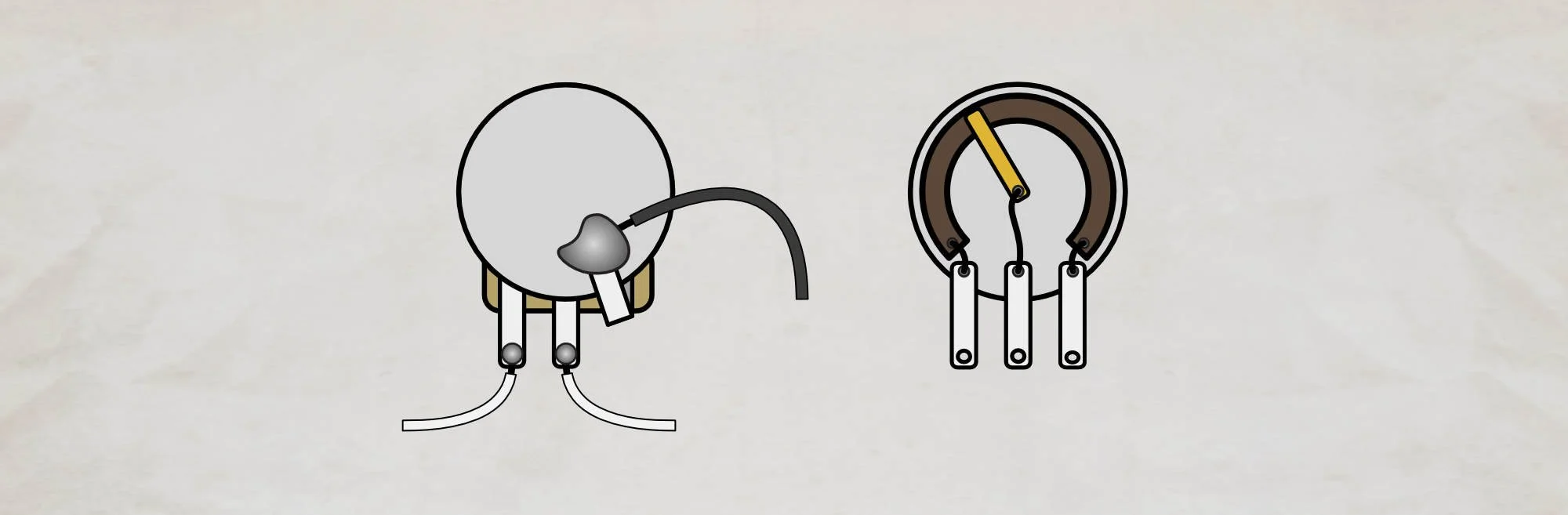

The covers on these vintage-style sealed tuners are really just pressed steel, They're not completely sealed—you can see the slight gap where the corners meet and at the bottom of the tuner post too. So, in the worn environment, it's not impossible for these to get dirty internally too.

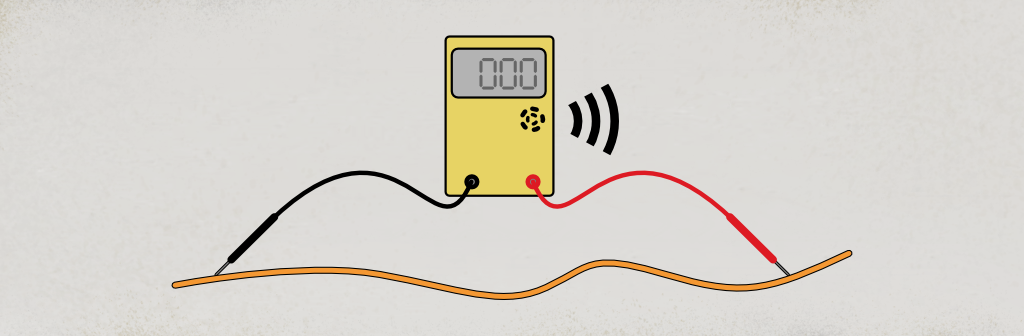

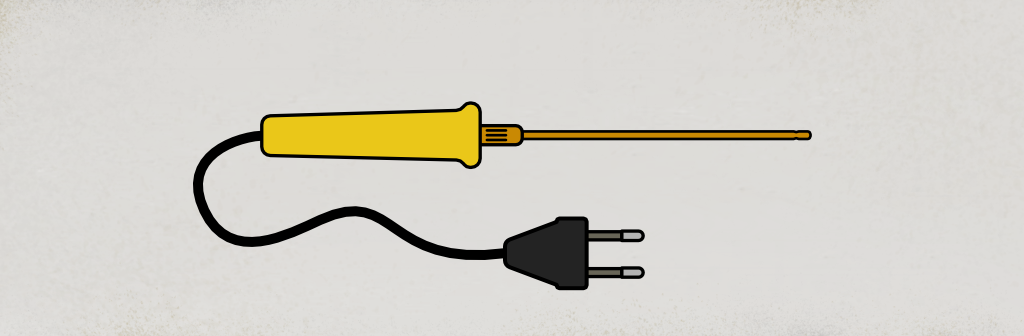

You'll also notice a hole in the back of the tuner. That's handy for us. We're going to try clean the gears through that hole. We'll need some naphtha again so precautions apply. Protect yourself and your environment. Wear glasses and work outside if you can—this stuff's nasty. Dispose of any rags or paper towels very carefully as it's also incredibly flammable.

We'll use a syringe or a pipette to inject naphtha through that hole in the case. Before we start, though, I saw Dan Erlewine give a great tip on this job. Gently heat the tuner first. Dan used the oil radiator in his workshop and left the tuner sit on it for a few minutes. Obviously, with plastic buttons, you don't want this thing getting really hot but, a little heat will begin to soften any grease that's inside the tuner, making it that much easier to get out.

Start squirting the naphtha in. Be careful as it may squirt back at you (remember those glasses). If the gods of tuner gunk are on your side, you'll start to flush out some diluted grease and dirt. Keep at it, trying to turn the tuner as you go. All going well, it should start to free itself as you clean.

If you're not having much luck, it might be worth giving it a soak. Submerge the tuner case in a container of naphtha and leave it for a day. Try the injection flush again and you should have more luck.

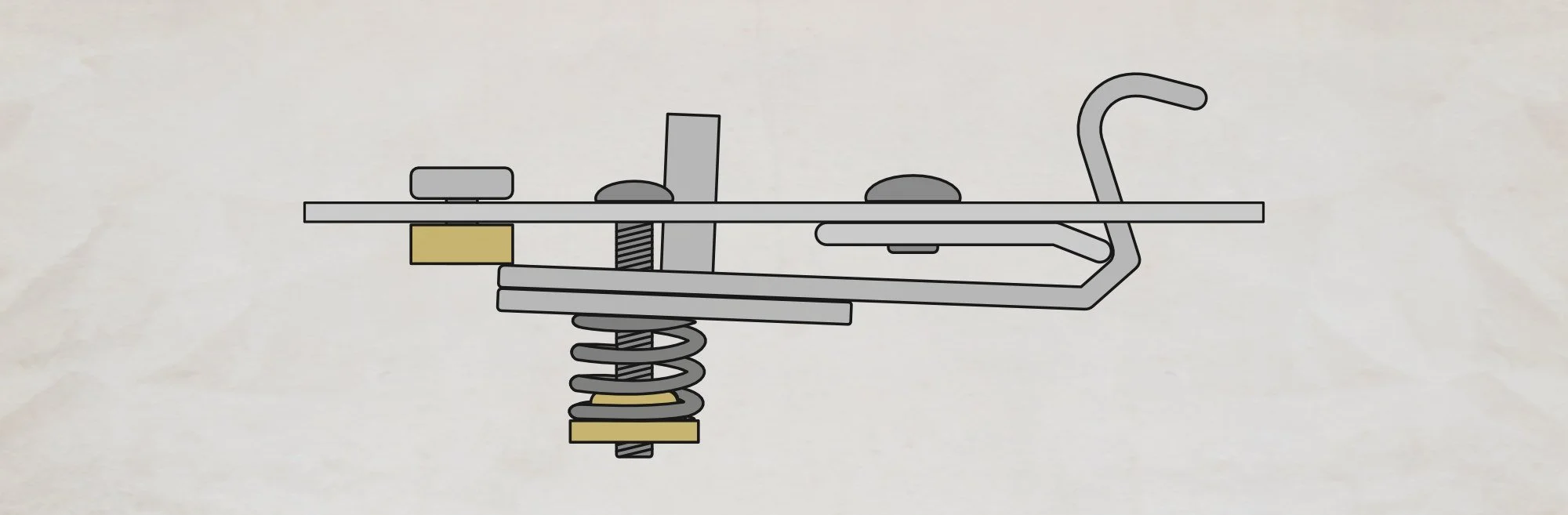

If you're still stuck, you can consider trying to open the case. Around the front of the tuner plate, you might discover that the case is held on by tabs that have been folded over. Now, I'd leave this as a last resort to be honest as it's a little difficult to remove—and especially to reinstall—the case. And it's not always possible so, do leave it until you're desperate.

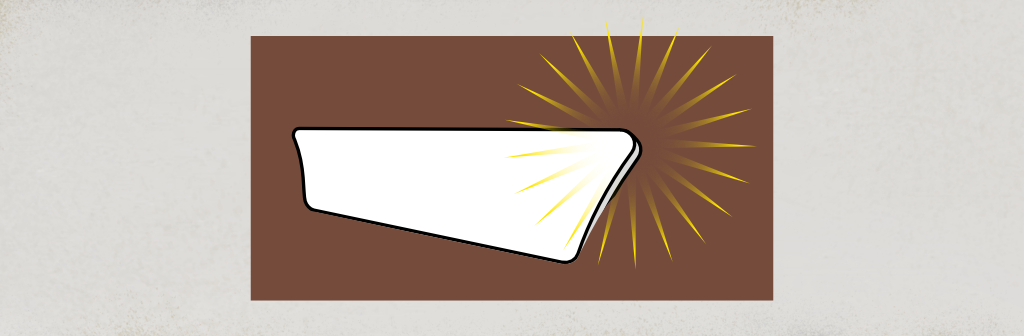

Once your tuner has been flushed clean and is turning more freely you can consider lubrication (wait for it to dry off first). You can just go with a little Tri-Flow here. A drop through the hole onto the worm gear will spread to the pinion after a few turns of the button. A single drop at the post 'bearing'/mounting points is awkward with the case but not impossible.

That may well be enough. Or you could grease it up. Grease is not without it's downsides. It can act like a dust and grit catcher, which can work that dust and grit into the gears over time. It's not as bad as oil residue but it can be problematic. However, when it's mostly sealed away, like here, it's pretty safe.

You can pack something like Vaseline in (either with a toothpick or, better, a syringe) but I don't like Vaseline for this job. I prefer white grease and I've found this stuff (above) that's got PTFE in it, has a good viscosity, and comes with a handy little applicator nozzle that's perfect for this job. This is called GEWA Micro Teflon Grease and, in Europe, it's available from [Thomann][0] (online music megastore). Outside Europe, something like SuperLube 21006 is available in a similar, syringe applicator and should do the same job.

Personally, I'd avoid the spray-can grease and go with the thicker, viscous, old-fashioned grease stuff. That may just be because I'm an old man who's set in his ways, or because I haven't use the spray stuff enough to have a good feel for it. Or both.

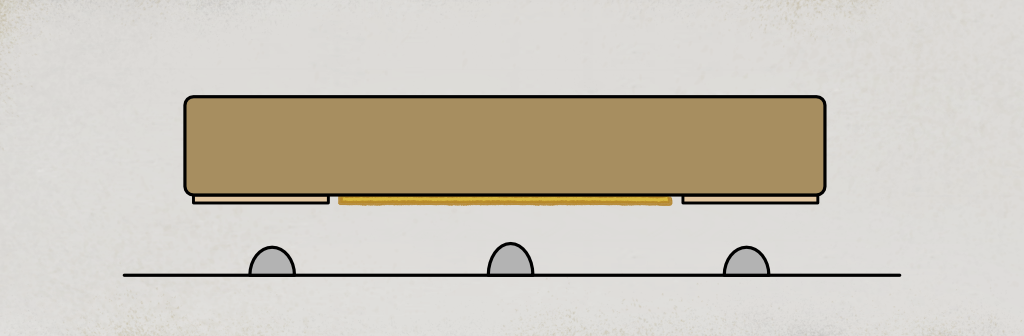

Modern sealed tuners

What about the more modern, more sealed tuners? How do I get into these things? [0]: https://www.thomann.de/ie/gewa_micro_teflon.htm

First off, remember how I said that the covered tuners rarely give problems. Well, problems with these modern tuners are even more rare. And, depending on how modern they are, if they're acting up, there's a good argument for just replacing them.

This is partly because they're not easy to service. I've seen people forcing the cover off the back to get at the gears but that's not easy to do in a non-destructive manner (and not always possible).

If you unscrew the tuner button you can (maybe, possibly) work some Tri-Flow down from the top of the shaft, into the internals. Sometimes, with the tuner button off, you can turn the post to work it out the bottom (see above) and apply some lube here before reinserting. You might have some success with these these solutions but neither is a great option.

With these tuners, I'd recommend trying the post lube options and, if not successful, just replacing them. 🤷♂️

This article written by Gerry Hayes and first published at hazeguitars.com