Sticky Tuners III: Final Tips

Just going to round off all this tuner talk with a final few thoughts on unresponsive or sticky tuners. Over the last couple of weeks, we looked at cleaning and lubricating tuners to help them work more smoothly. I mentioned that, after slackening off the strings—and after removing the troublesome tuner from the headstock—you should give it a couple of turns to see if it's any more free. That's because, sometimes, the problems with tuners aren't really with tuners. Here's a couple of thoughts:

Tuner mounting woes

It's pretty rare that a tuner mounting hole will be too tight and cause a tuner to bind up. Most instruments have bushings around the front and, if these are fitted, things will generally be fine. Classical-style slot-headstock tuners with plastic or bone sleeves can sometimes bind, mainly because they're a bloody terrible design. More modern versions of these tuners feature bearings to provide smoother bind-free operation.

Misaligned or misplaced mounting holes can be a problem, though.

Misaligned is relatively obvious. If the hole is not drilled perpendicular to the rear of the headstock (where the tuner body will mount), the string shaft may not pass through cleanly and can get pushed out of alignment on its way.

A similar issue can happen when dealing with multiple tuners that come fitted to a plate. Three-on-a-plate tuners, for instance, require each post hole to be very accurately located. If one is off, it can pull the whole unit out of position and cause some or all of the posts to be misaligned. Not great.

These problems can often be addressed by widening the post hole from the rear. A reamer is the best bet for this. By increasing the size at the back of the hole, the post(s) have more room to pass through without snagging anywhere. The bushing at the front has to stay where it is to keep the tuner post supported. That means, really badly aligned stuff would probably need to be plugged and re-drilled but things aren't typically so bad you would need to do more than ream the rear.

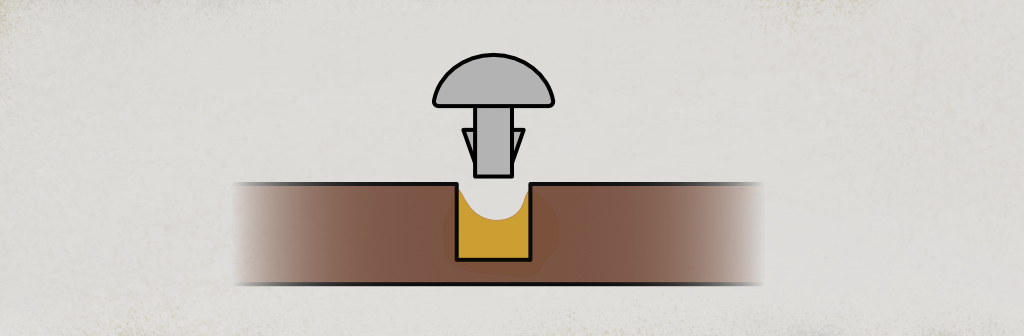

Bushings

I've heard of people polishing string posts and the inside, bearing surface, of bushings so that the tuner operates more smoothly. I've never really found it necessary but, if you feel like doing so, it probably can't hurt. Although, you do want to make sure you don't end up polishing enough that you flake off any plating that might be on either part.

A tiny (really tiny, remember) amount of teflon grease at the bushing-post contact point is something that, again, can't hurt (providing you don't go nuts with oil or grease—just a pin-head drop).

Missing bushings can cause the tuner string shaft to deform under string tension. The mounting hole is larger than the shaft and it now has room to pull towards the bridge.

If you notice one is gone, try to replace it as soon as you can.

Physical Damage

Finally, remember that, even when a tuner remains sticky and unresponsive after being removed from the guitar, the problem may not be dirt or lubrication-related. Check them for damage. It's actually relatively easy for a tuner to get a knock. In the worst cases, the thing will fall apart—usually the button will crack or fall off. Sometimes, especially with modern metal-buttoned tuners, things can just get bent out of shape without too much visual indication of a problem.

Look closely at the shaft (or the 'line') from button to the tuner body. Any slight bends or kinks. Depending on how and where a kink occurs, the tuner can become difficult to turn. For open tuners, check for any damage to the bearings that hold the post and worm gear. Lastly, look for any misalignment of the string post. It can sometimes be knocked out of whack so it (and the pinion gear) don't turn so freely.

Often damage like this means the tuner is difficult to turn for just one 'section' of its revolution. It might be really stiff for a turn or two and then free up for a bit before becoming stiff again.

Most of the time, physical damage is probably best resolved by replacing the set of tuners. For really vintage stuff, where originality is important, it's possible to repair some tuner damage but it's usually not easy and often requires some pretty involved metalworking. Not every repairer is (a) able for it and (b) up for it. It tends to be relatively rare that this level of original-part repair is needed, though, and most people are cool with popping on a new set of tuners.

Incidentally, a slight aside on that last point. If you've a nice guitar, do replace the whole set of tuners. It's perfectly fine to have odd, spurious tuners from the spares bucket on your beater but, for something nice, treat it to a full set if you have to replace one. It'll look and feel better.

This article written by Gerry Hayes and first published at hazeguitars.com