Troubleshooting Tuning: Tremolo (Pt. 1)

We took a bit of a detour in getting here but we’re finally at tremolo. Pedant Note: I’m going to use ‘tremolo’ throughout rather than ‘vibrato. That’s just the way it is. I know it’s really vibrato. I’ve talked about this tremolo vs. vibrato before, remember.

Now, this is a bit of a two-sided issue because, on the one hand, there’s potentially a whole book’s worth of material to be written on the various tremolo bridges. And, incidentally, repair-supremo, Dan Erlewine was already dedicated a good portion of a book to this subject. You are very strongly recommended to check out Dan’s book, “How To Make Your Electric Guitar Play Great” (Amazon US | UK Affiliate Link) because it’s fantastic. Quite honestly, much of what I have to say on this subject here is covered in way more depth in that book.

Right here, I’m just going to concentrate on some of the more directly tuning-related issues. Dan’s book goes into more detail on the maintenance of different tremolo bridges. Seriously, just go get it.

And, on the other hand of that two-sided issue, while there is heaps you can say about tremolo tuning stability, if you’ve read the other posts in this series, you’ll be really well equipped to keep any guitar in tune. If you can digest and use the stuff we’ve already covered over the last few weeks, there’s a very good chance your trem will already be much more stable.

What do you mean by out of tune?

Locking Tuner Advice Debunked?

I’m going to assume that’s the case and just add some extra considerations for tremolo bridges. Think of this as a Tuning Bonus. 😉

A last caveat: Like I say, this is hugely broad area. What follows is a (somewhat) random pile of tips. Some are applicable to all trem types and some only to Strat or Floyd-style trems. Essentially, I’ve brain-dumped a heap of top tips for taming your tremolo tuning.

Alliteration is fun, isn’t it?

As it turned out, I ended up with quite a few so I’m splitting it over two posts. More to follow next time.

Ease the String’s Path

This applies to all instruments. The less friction in the path, the better and the fewer bends or ‘kinks’ in the path, the better.

So, revisit nuts and string trees. Use some fine sandpaper (1000 grit or above) to carefully polish the bottom of your string trees. Wrap it around a string to polish nut slots.

Same goes for saddles. Eliminate any hard corners you can. On a tun-o-matic bridge, round-off the rear of the string slot through the saddle.

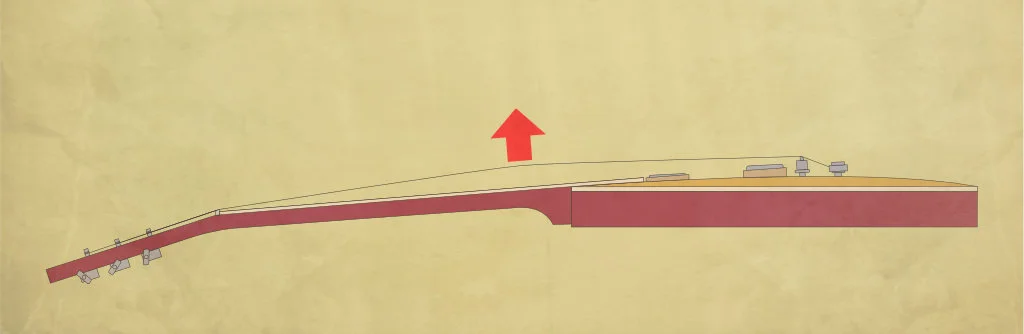

You can even take that as far as ‘ramping’ the base of your Strat bridge (where the string comes out of the block and bends towards the saddle.

You'll need to disassemble your bridge for this job. Your can make the ramp with a file but a Dremel tool is better. However you accomplish it, spend most of your time removing scratches after you do it. Use a number of grades of sandpaper wrapped around a thin tool. Stew Mac offers Mitchell Abrasive Cord and you’ll get it easily on Amazon too (US | UK - Affiliate Link). This cord is really great for doing the bulk of this polishing and is brilliant for saddles, string tress, and nuts too. It comes in gauged sizes so you can really get into the nooks and crannies.

Cut out as much friction and sharp string-kinks as you can. It’ll pay off.

Roller bridges and string trees

My own feeling on these is that the ‘roller’ aspect is a little over-hyped. They’re not frictionless bearings or anything. However, in the case of the bridges, even if they never actually roll, the roller saddles do offer fewer hard corners than a standard tun-o-magic.

Personally, I think that a well set-up bridge that’s had the string paths smoothed, eased, and polished will be up to the task as well as a roller bridge but feel free to go rolling if that polishing work’s causing you hassle.

On the string tree end, they’re definitely worth a try if you’ve tracked your tuning woes down to that particular location.

String Trees

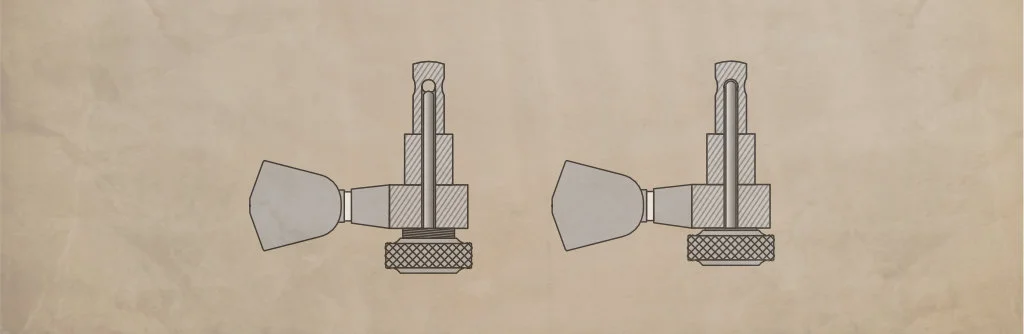

While we’re on the subject of string trees, you can remove them temporarily if you’re tracking down tuning issues. Leaving them off isn’t a great option, even with staggered height tuners. You just won’t get a good break angle for the top two strings.

If your trem is more stable without the trees, try cleaning and polishing their underside. When replacing make sure you use the proper height-spacers. Don’t screw them right down to the face of the headstock. This can actually give too much break angle over the nut and add kinks and friction-points into the system.

If your string tree is currently screwed right down to the headstock (many are), consider buying a new set, complete with spacers, to install.

Permanently-lubricated nuts and saddles

I’m including those little String Saver saddle ‘inserts’ in this. These are the nut/saddle materials with a lubricant like graphite or PTFT ‘impregnated’ into the plastic.

I touched on it before but I don’t like these. I find them too soft and I think that any benefit the impregnated lubrication might provide is quickly offset as the strings dig in and mar, or deform, the material.

Lubrication

What about applying your own lubrication?

Sure. Lube ‘em up. A little judicious application of a lubricant can only help. Don’t go crazy though — a little goes a long way.

I like Big Bends Nut Sauce (Amazon US | UK – Affiliate Link) but don’t assume that’s the only option. A little Vaseline will do the trick if you want. I also use Stew Mac’s Guitar Grease which is a graphite paste. Pencil graphite dust is ok in the nut (although it can discolour it) but it doesn’t tend to stay in place as well at saddles or string trees.

Start with the obvious points like the nut and the string trees. Apply a little lube there. If needed, add a little where the string contacts the saddle. And, on a Strat, consider where the string ramps out of the block over the bridge base. Even a little at the knife-edges is worth trying.

Like I say, just a little of this stuff. You don’t want it smearing around so it gets on the wood or your hands.

OK. So, that’s your lot for now. Join me next time for another trip down the tremolo tuning trail of triumph.

Sorry. 😉

This article written by Gerry Hayes and first published at hazeguitars.com