Lifting inlay lifts no more

Loose fingerboard inlay this week. It happens from time to time. Often, you’ll find just a corner sticking up. Deal with it now and maybe the whole thing won’t come loose. Or, at very least, your fingerboard won’t have an annoying corner sticking up to catch your fingers/strings as you play.

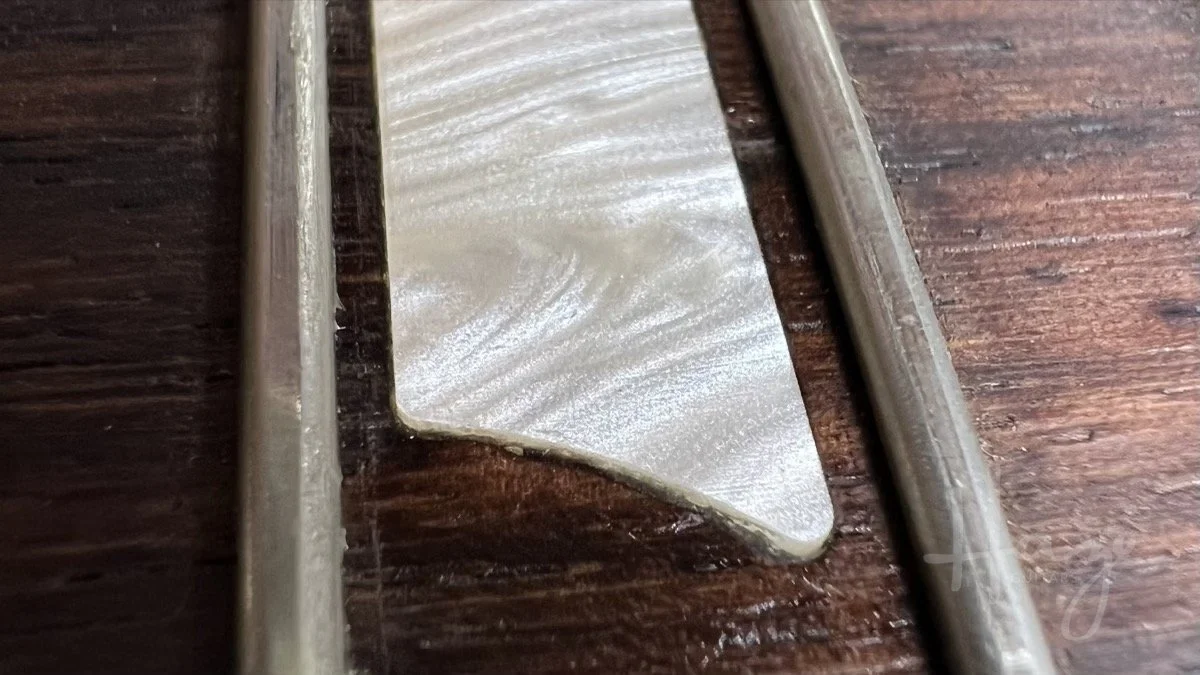

So let’s deal with it. This one’s nice and straightforward. It’s just one end of this Les Paul’s crown inlay and it goes back down pretty cleanly with a little pressure. It doesn’t press back absolutely flush with the fingerboard but it’s close enough that I can deal with it without too much trouble.

If this was less flush—or if it didn’t press back nicely—I’d remove the inlay from the fingerboard before going on. That’d let me clean up the bottom of the inlay and the rout to get a good fit before re-glueing. As it is here, we’re in good shape.

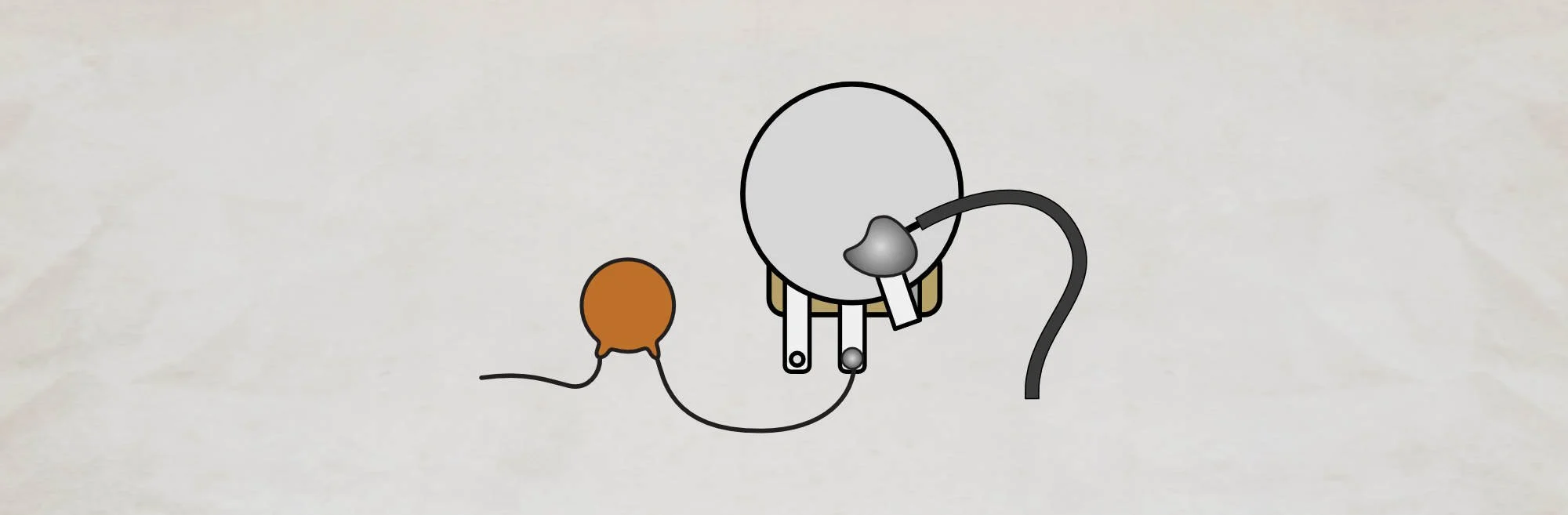

To keep this inlay down, we’re going to wick in some low-viscosity superglue. The water-thin stuff is great for jobs like this because it gets drawn into thin cracks and spaces. It avoids the need to remove the inlay completely in order to work glue underneath.

First though, I’ll use a cotton swab (Q-Tip) to spread a little wax onto the fingerboard around the inlay. The wax layer prevents the superglue from wicking into the surface of the wood. Vaseline works for this purpose too. Some care is needed to avoid sealing up the gaps around the inlay which would prevent the glue wicking where we actually want it. Don’t just smear this stuff on. You just need a little.

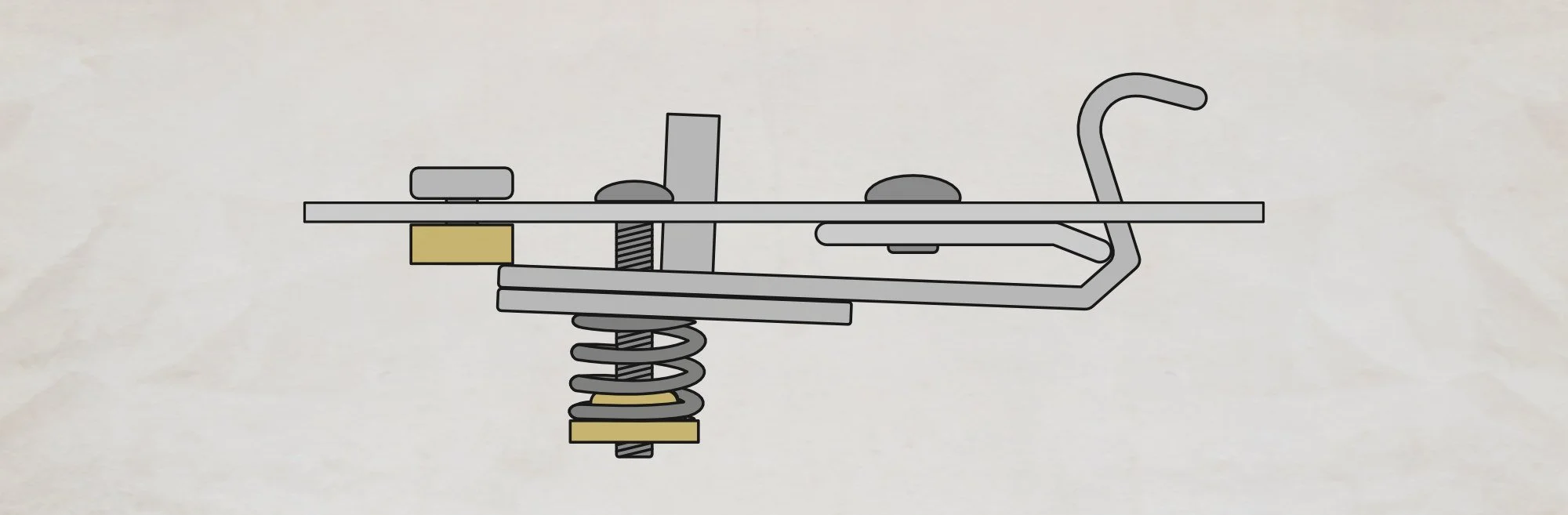

You can just see the wax sheen on the fingerboard in the photo above. I’m using a ‘whip-tip’ applicator on my superglue bottle. It makes for a much more controllable application.

What you can’t really make out in this photo is that I’ve got the guitar held at a slight angle so that the glue will flow downhill a little. There’s an argument that it’s not necessary but I like to give it every chance to get good penetration. There’s some strips of blue tape at the other side of the fingerboard. In the (hopefully unlikely) event that any superglue runs too far, I don’t want it getting on the finish. I’ve got plenty of paper towels on hand to catch runs quickly if needed.

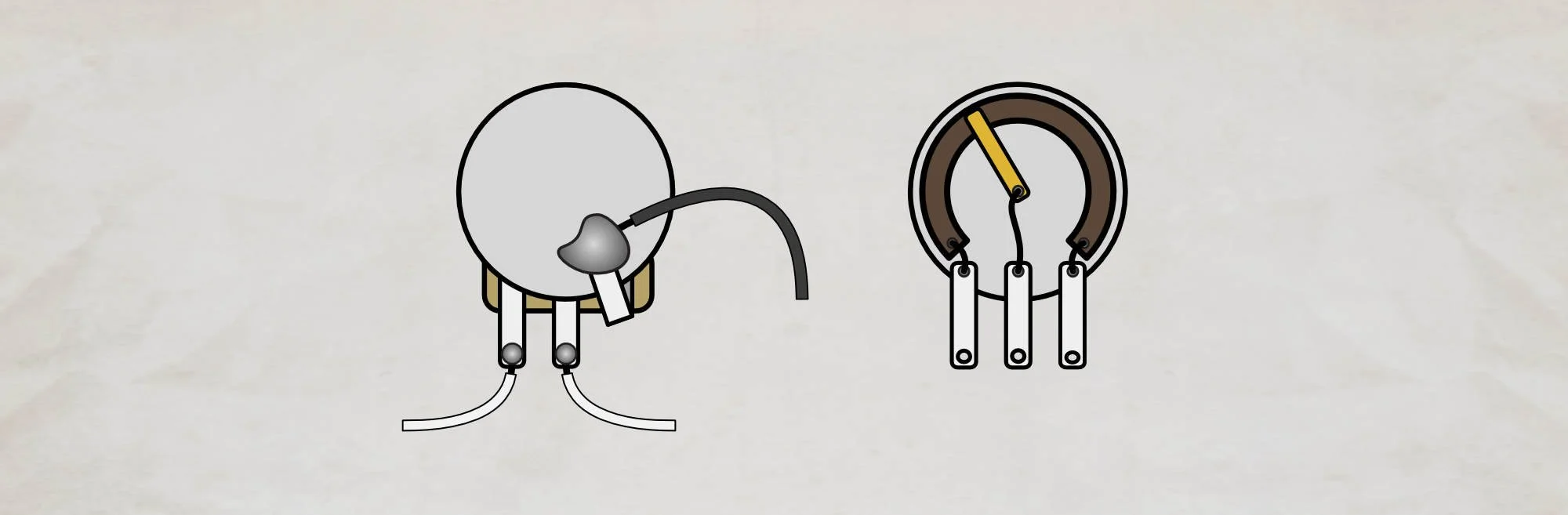

The important part of any glueing is how the parts are held while the glue dries. Superglue in these circumstances doesn’t dry as quickly as it does when it gets on your fingers so the inlay needs to be held down firmly until the glue cures and grabs. I fashioned a narrow caul and clamped things here. It’s possible to hold it if you’re patient but you do need to keep it pressed firmly and consistently for a good glue joint. I wouldn’t advise using your finger. The eraser tip at the end of a pencil would work well here, though. A squirt of CA accelerator might help speed the curing time too (although, keep in mind that it won’t reach the glue deep under the inlay so well).

When the glue was dry, there was a very slight lip where the inlay didn’t sit completely flush with the board. I used a razor blade to scrape the part that still protruded above the fingerboard. These inlays are pearloid so that’s pretty easy to do. They’re also pretty new and I knew there was plenty of thickness to allow me to scrap without fear of thinning it too much.

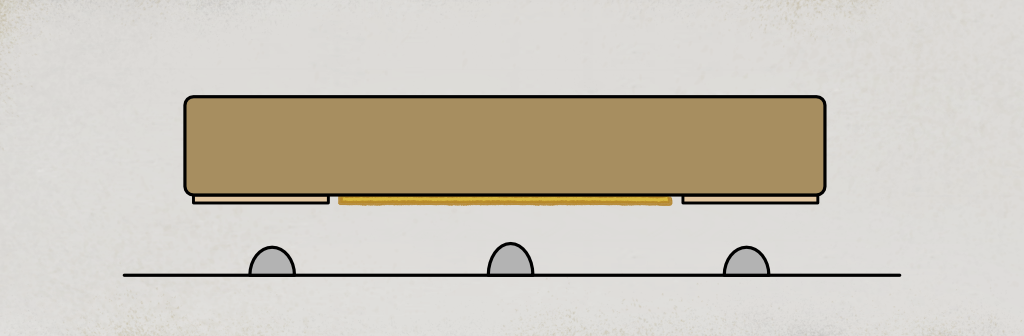

Once I had things flush, I had to clean things up. For this, you can use those little abrasive ‘fret rubbers’ to sand and polish the fingerboard between the frets.

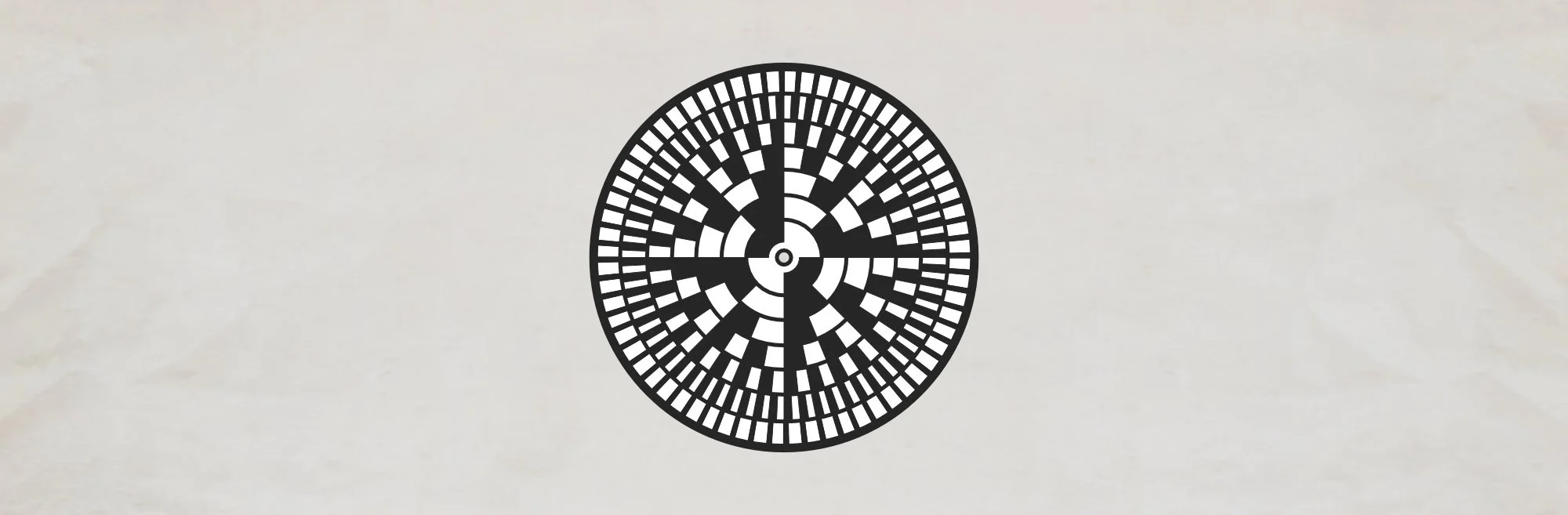

These fret rubbers are an abrasive material suspended in a small block of rubber. Stew Mac sells them in seven grits as ‘fret erasers’ *

The fret rubbers can get right up to the fret edge which requires more effort and care with sandpapers. So, a relatively quick run through with successive fret rubber grits and we end up with a nice, clean, flush inlay in a nice, clean fingerboard. Job done.

* The Atlantic language divide gives our US cousins ‘eraser’ while over in Ireland and the UK, we go with ‘rubber’. From the emails I get when I mention fret rubbers, some people in the US find this hilarious.

This article written by Gerry Hayes and first published at hazeguitars.com