Neck Resets 4: Useful Neck Reset Tools

Last time we talked, we’d just gotten our glued-in neck separated from our guitar body. And, we could charge into discussing how to proceed with the actual business of resetting the neck angle but I want to take a detour. I think it makes sense at this point.

I want to talk about two devices that might be able to make the work of getting the neck off the body a little easier.

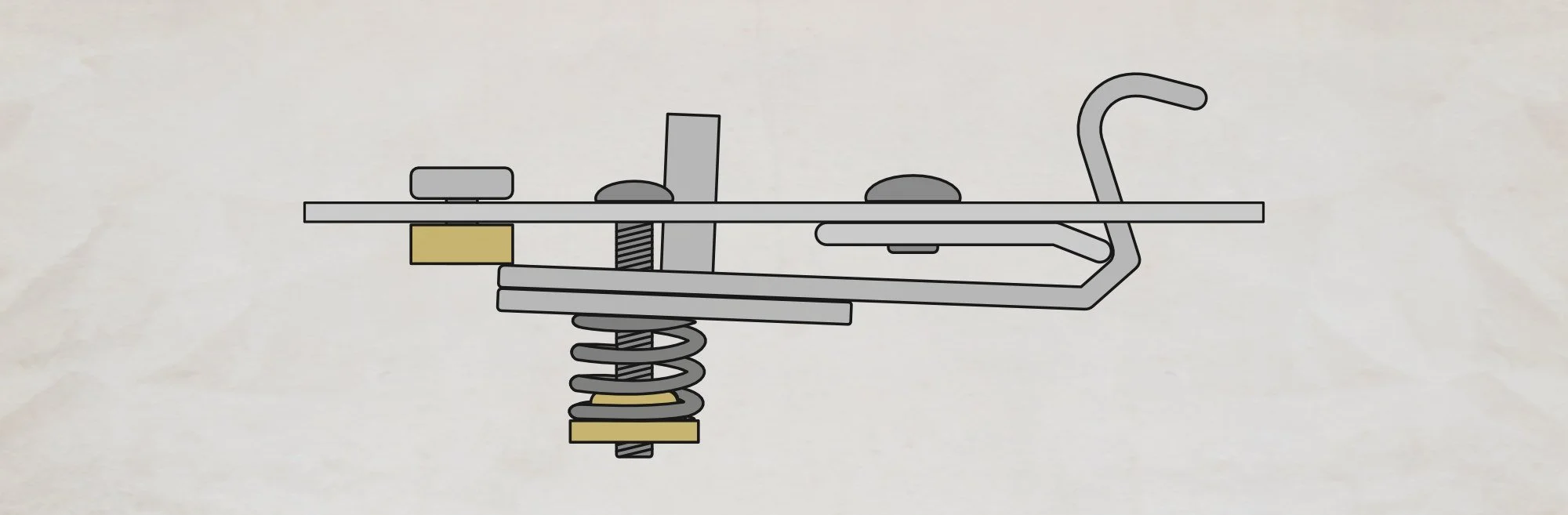

The first is what Stew Mac calls a neck removal jig. It’s a relatively simple device — really just a bundle of threaded bars, a bit of plywood, and a bolt with a knob on the end. Like many others, I used to use a much less elegant, homemade version of this. I eventually replaced it with Stew Mac’s version (when you do this stuff for a living you often weigh up costs against time differently). Mine was a little flimsy and I was happy to upgrade.

If you’re experienced enough to attempt a neck reset, though, you should certainly be able to rustle up a similar jig without too much of a problem.

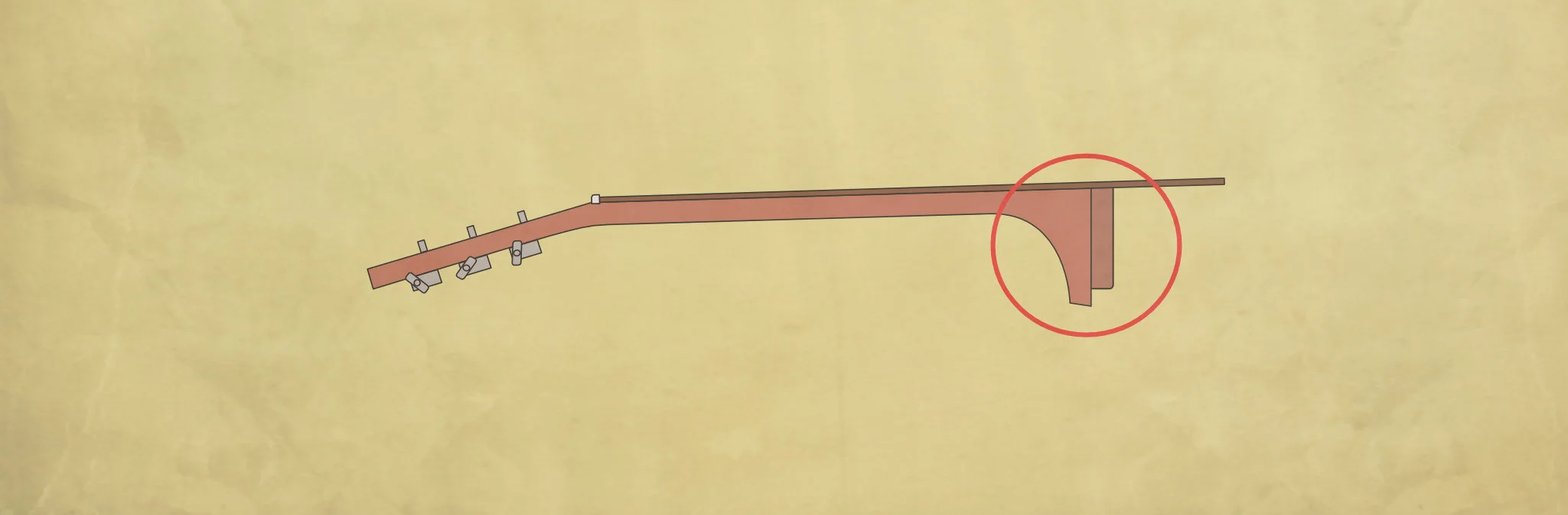

The jig attaches over the shoulders of the guitar and the knob turns a bolt that presses against the heel cap. You can tighten this bolt up to provide pressure ‘upwards’ so that, as you wiggle and wrestle the neck from side to side, it’s also being encouraged up and out of the joint. As you work, you can add a little more pressure as things begin to shift.

This is really handy. You can just concentrate on working the guitar back and forth in two dimensions as the jig bolt applies pressure in the third dimension.

It’s definitely not essential but it definitely makes this job easier.

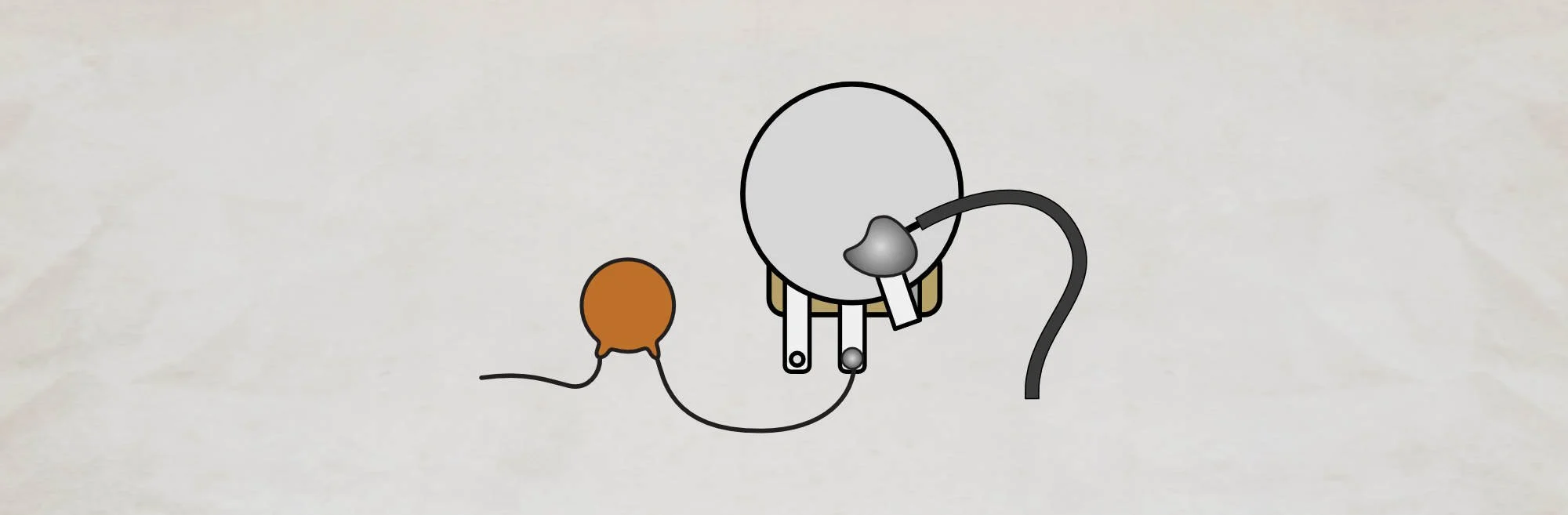

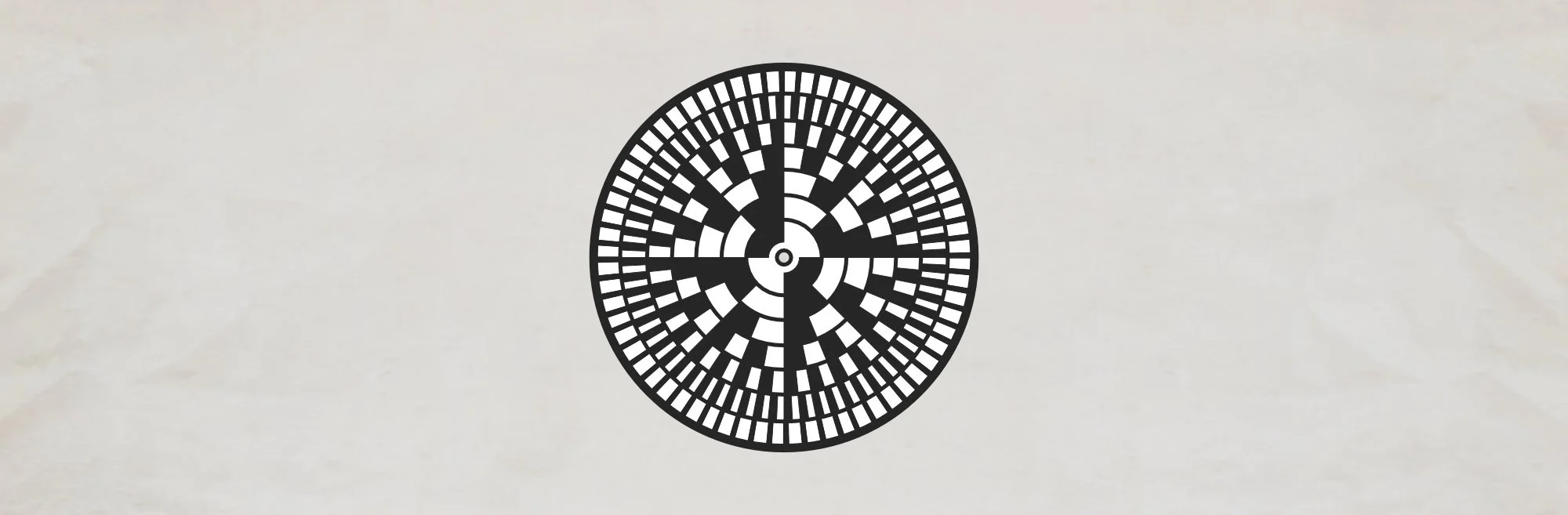

The second device is somewhat new to me. We’re back to Stew Mac again for the HeatStick. You can think of this like a long extension bit for a soldering iron (because that’s what it is). The idea is that, instead of injecting steam — with all of the associated risks and drawbacks — you can use the HeatStick to heat the glue in the joint until it gives way.

I was somewhat sceptical of this when I first read about it and I resisted for ages. First off, I didn’t believe it would work terribly well. To my mind, the dry heat couldn’t penetrate the joint as well as pressurised steam. Also working against it, in my mind, were the fact that it needed a larger hole drilled in the fret slot and that early reports suggested there was some charring to the neck block and top.

I resisted until quite recently when I had a particularly nasty neck break to fix. The neck had broken at the heel, leaving the heel glued into the neck block but no neck left for ‘wiggling leverage’ while removing. I’ve had these before and always triumphed (after some considerable effort and swearing) but this one had me beat. Steam wasn’t doing it and I needed that neck out for a good repair.

As a last ditch, I bought a HeatStick to try.

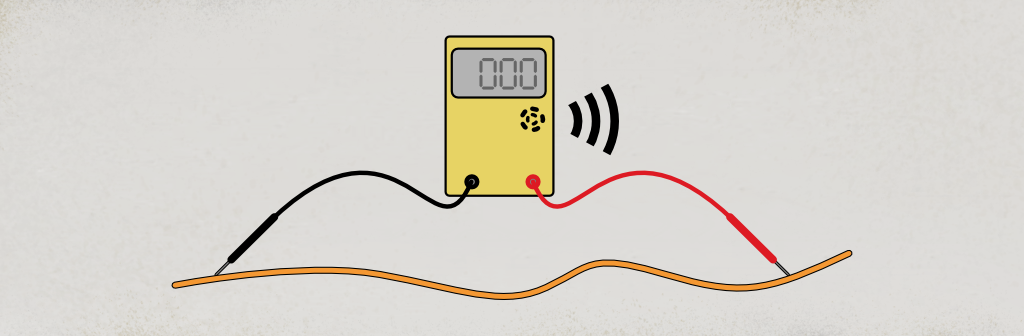

It worked fantastically. I don’t use that word lightly. I jigged the guitar and applied a little pressure to the heel cap. I made a suitable hole and inserted the HeatStick. I expected to be there for ages, maybe working via several more holes over an hour or so (if it worked at all).

My scepticism vanished as the dry heat and the jig pressure suddenly popped the troublesome neck heel free without any effort from me. I wasn’t even looking at it. I heard pop from the bench beside me and stood there gawping at the separated heel with a stupid expression of comedy-surprise.

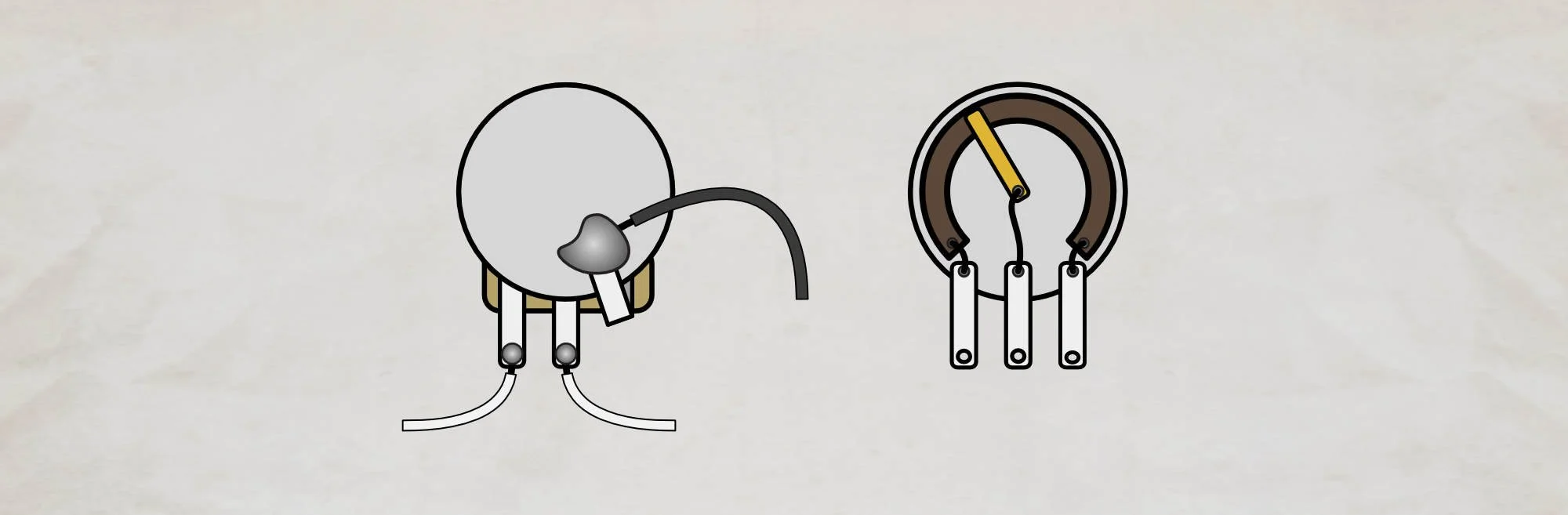

I’ve since used the HeatStick a couple of times and I think I’m a convert. Yes, it needs a bigger hole. But repairing a hole in the fingerboard — partially concealed beneath a fret — is usually pretty discreet. I have seen only a little charring. It hasn’t been significant and it’s been hidden. And, I reckon that weighing these against the potential troubles of steam, generally comes down in the HeatStick’s favour. If I can avoid the risk of damage and blushing on delicate finishes and prevent errant damp-heat and moisture in places I don’t want, that’ll take a lot of the stress out of neck resets.

So why did I write a thousand words or more about steaming necks the last time we talked? Well, I’m still early in my HeatStick journey. There may well be circumstances where steam is the best option. I don’t know yet. I’ve gone back and forth over the last couple of months, mostly through a slight residual wariness of the HeatStick (which seems to be proving utterly unjustified).

If you have a compatible soldering iron or (much more recommended in my limited opinion) a soldering station, I think you should definitely consider the HeatStick. Like I say, I’m new to it but I’m very, very impressed so far.

So, I hope this diversion has been useful. Next time, we’ll get on with resetting the neck angle.

A round-up of this neck reset series

This article written by Gerry Hayes and first published at hazeguitars.com

The final touches. Everything’s back together and the reset is done. Just a few last considerations.