Foam-Cutting Neck-Reseting

I was late to the party. There’s a new neck reset kid in town and all of the cool kids have already been hanging out with them for a while.

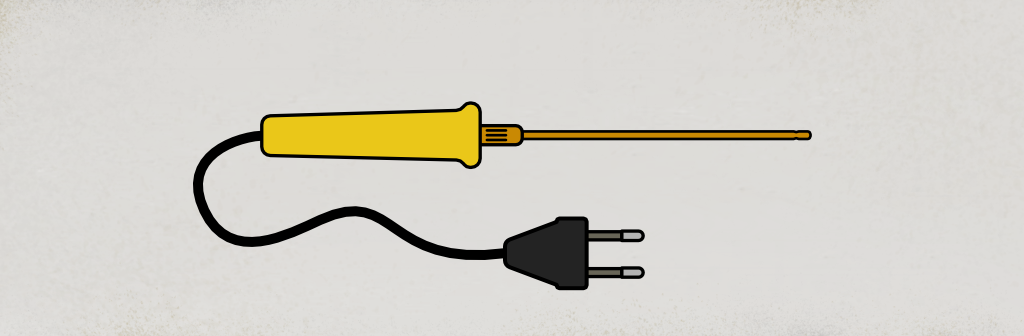

If you remember, some time ago we talked about neck resets. I showed the ‘traditional’ method of steaming off a glued in neck and then went on to discuss the Heat Stick which, when I wrote that, I’d only used a few times. Since that, I’ve used the Heat Stick some more and I really like it. It’s great at heating the glue in a neck joint so it releases. I think steam will still have a place but the Heat Stick does away with many of steam’s drawbacks. It’s not without its own drawbacks but, dry heat seems the way of the future. Long life the Heat Stick.

But, no sooner had I settled into life with the Heat Stick then I see Ted Woodford with a new tool. I’m not sure where it all started but I think that Ian Davlin at the Looth Group* may have been responsible for the idea (he often is).

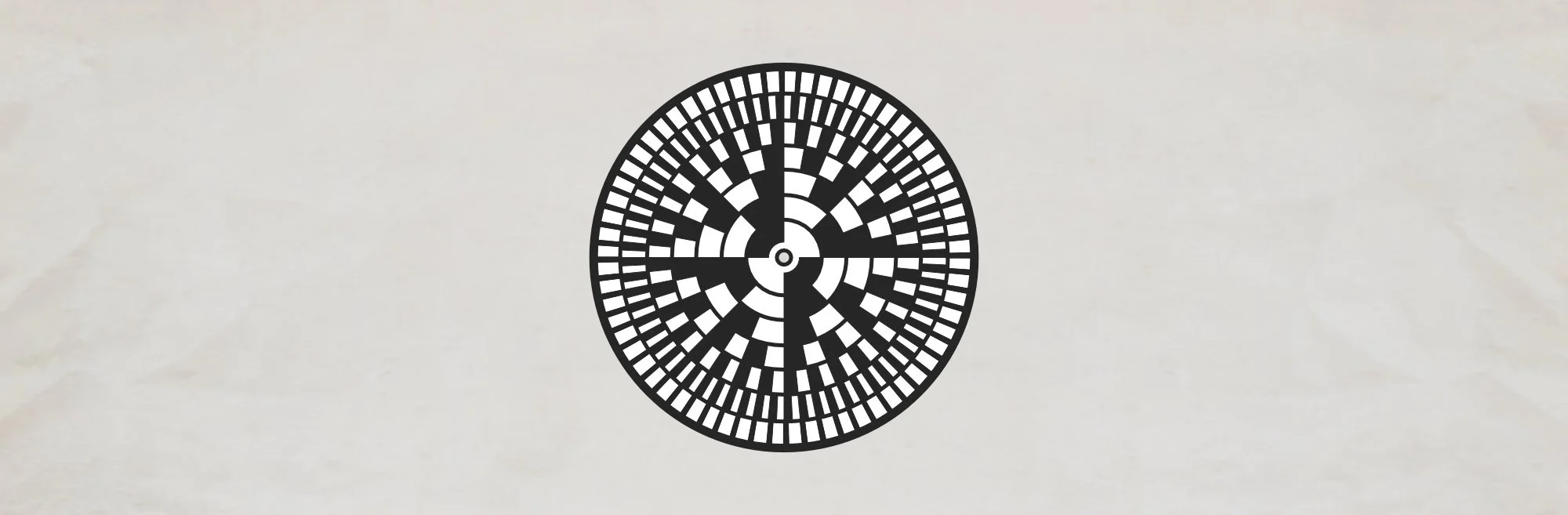

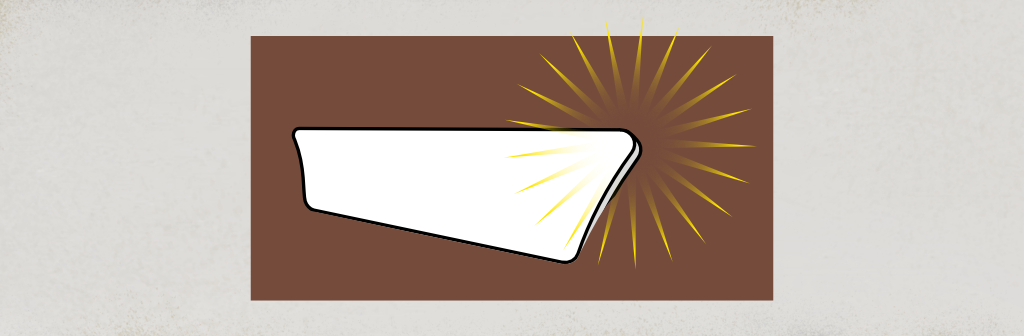

Turns out that the tool used for cutting through thick sheets of foam is a great substitute for a Heat Stick connected to a soldering iron.

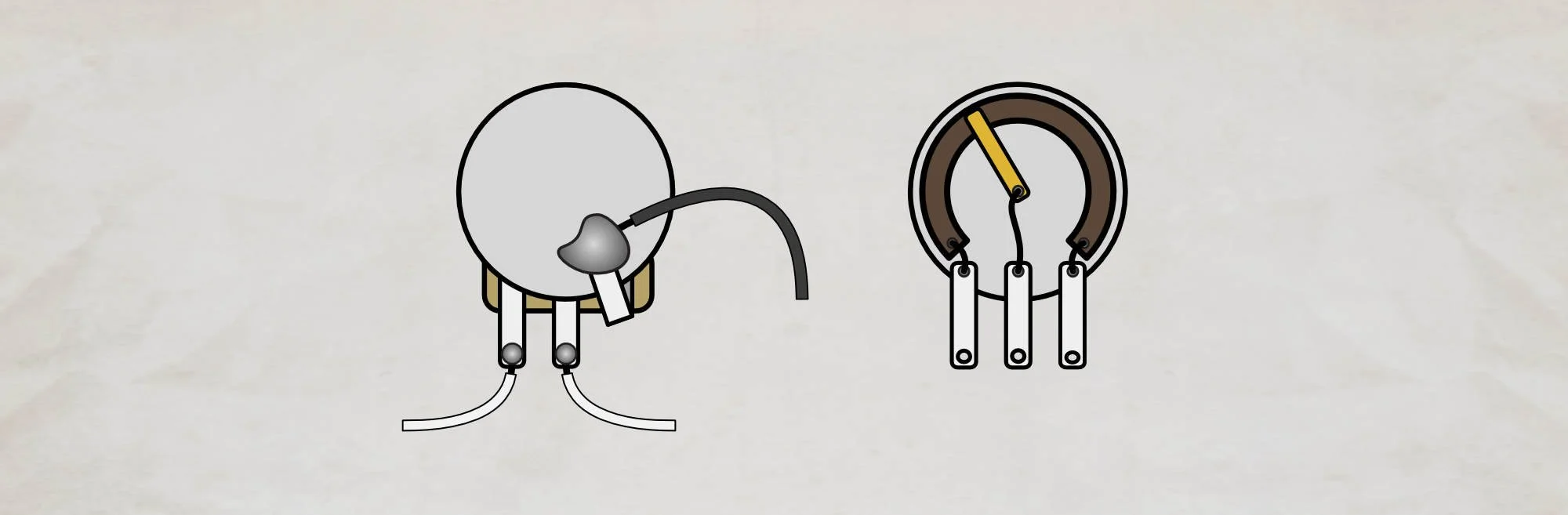

The hot foam cutter tool is pretty self-explanatory. It’s got a handle and a long, narrow heating element. The element gets very hot which is great for cutting foam, apparently. As it happens, it’s also great for substituting for a Heat Stick. I picked up a pair of these to try them out.

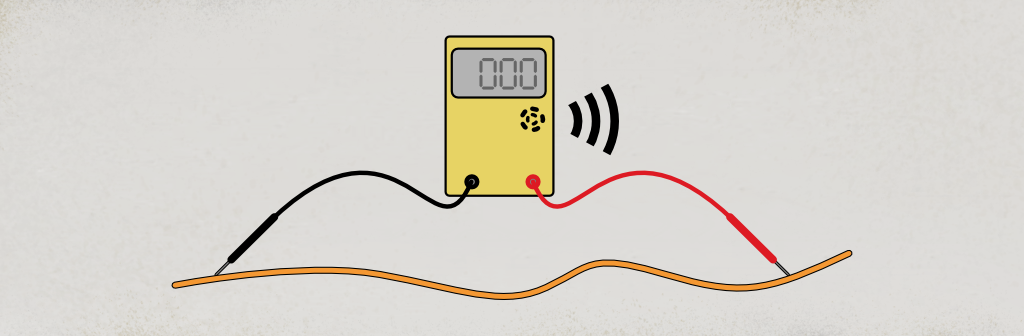

There are a couple of advantages here. The first is cost. You can pick up one of these things really cheaply on eBay. Related to this, you don’t need a soldering iron to attach a soldering iron (although, if you’re attempting neck resets, you probably have access to a soldering iron anyway). Because they’re cheap, you can get two and heat the neck joint from two sides, attacking the dovetail in a pincer movement. I actually did this after the photo above.

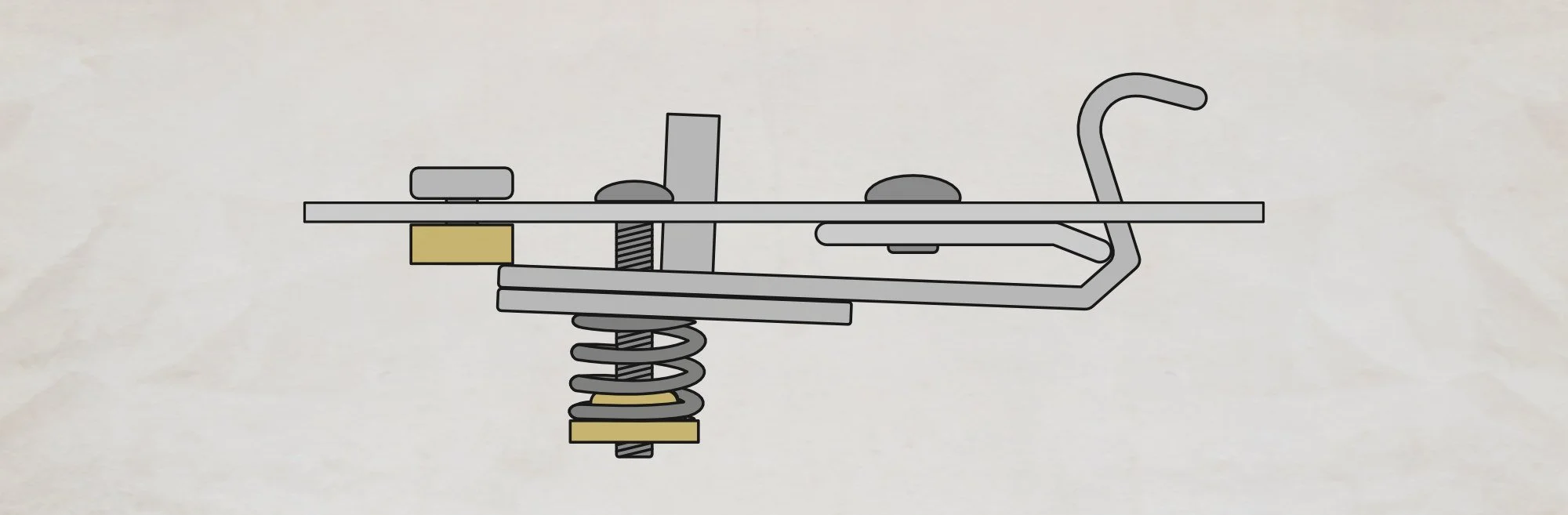

The foam cutter I used doesn’t require drilling quite so large a hole as the heat stick. You can get access for the foam cutter element with a smaller hole in the fret slot. I think I’ve subsequently heard Ted mention that the better (read ‘more expensive’) foamer cutter require an even smaller hole. That tracks—the end of the heating elements on my cheapie cutters are crimped off and flattened into a wider diameter than the rest of the element. The better cutters apparently get hotter and do so more quickly, too.

So, how did I find these new toys. Pretty good. Good enough that I’m probably going to invest in one or two better units. These worked just fine but I suspect hotter elements will make the job go more quickly. I also like the idea of a smaller diameter access hole. Although the Heat Stick got me used to the idea of a larger hole, smaller is always better here.

So, if you’re someone who resets necks (or is getting into resetting necks), these things are well worth checking out. The cost for the cheapies means it’s a reasonable experiment (and they’ll probably be fine for somewhat longer-term use). eBay or Google "foam cutter" or "foam cutter pen" and you should turn some up. Well worth a try.

And, if you’re not doing neck resets (which is pretty understandable), I hope this was enough to keep your interest. As always, hit reply if you gotta reply.

*Speaking of the Looth Group, I was invited on there a while back to talk about my book, Complete Guitar Wiring. It was a nice chat and they’re a good bunch to hang out with. Turns out they have an enormous archive of fantastic information and techniques and are tirelessly making more. Ian invited me to join and help out and I am doing just that. If you're a builder or repairer at any level, I think you'll find it massively useful. If you do this stuff for a living, joining up is a no-brainer. Seriously, check out the Looth Group.

This article written by Gerry Hayes and first published at hazeguitars.com